Wine industry

Arsilac, wine specialist since 2006

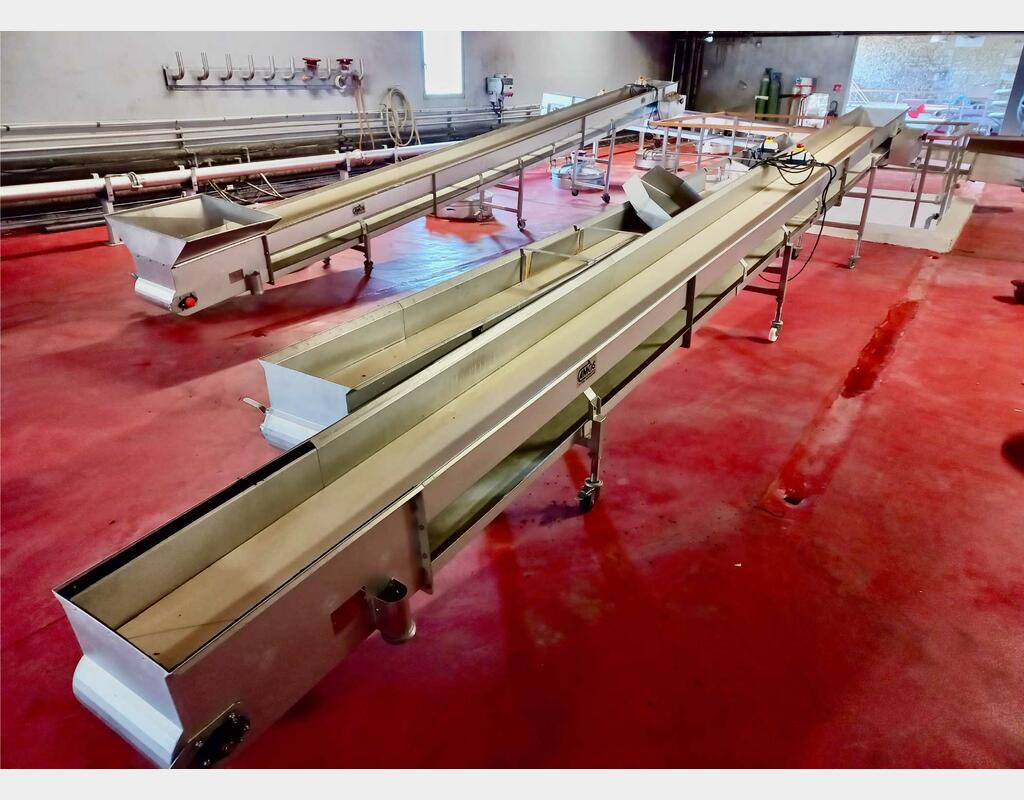

We offer a full range of wine-making equipment, from harvest reception to bottling. We work with the best brands, meeting the most stringent industry standards. New or used, our range of equipment covers pressing, temperature control, storage, vinification, pumping, grape reception and bottling.

The cellars

We work with engineering companies or on our own to design and build wineries, with or without access and guardrails. We can meet your design requirements thanks to our CAD tools and our experience. We can present you with photo renderings of projects that will allow you to project yourself into your new investment and refine the concept and design before completion.

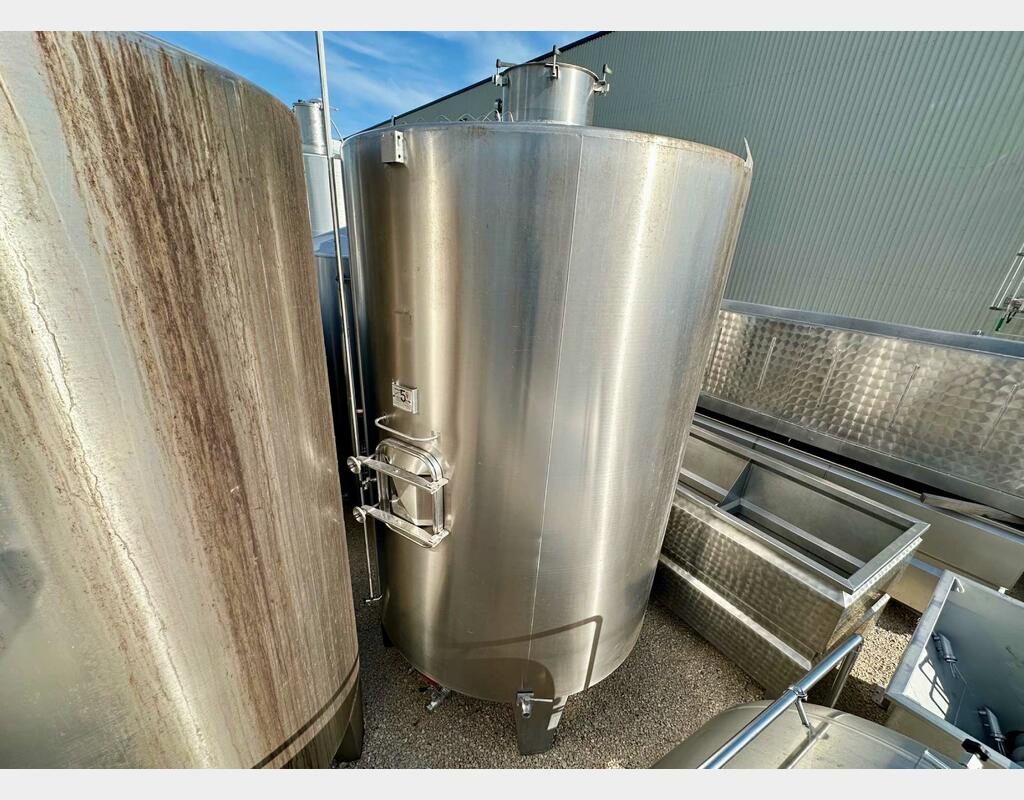

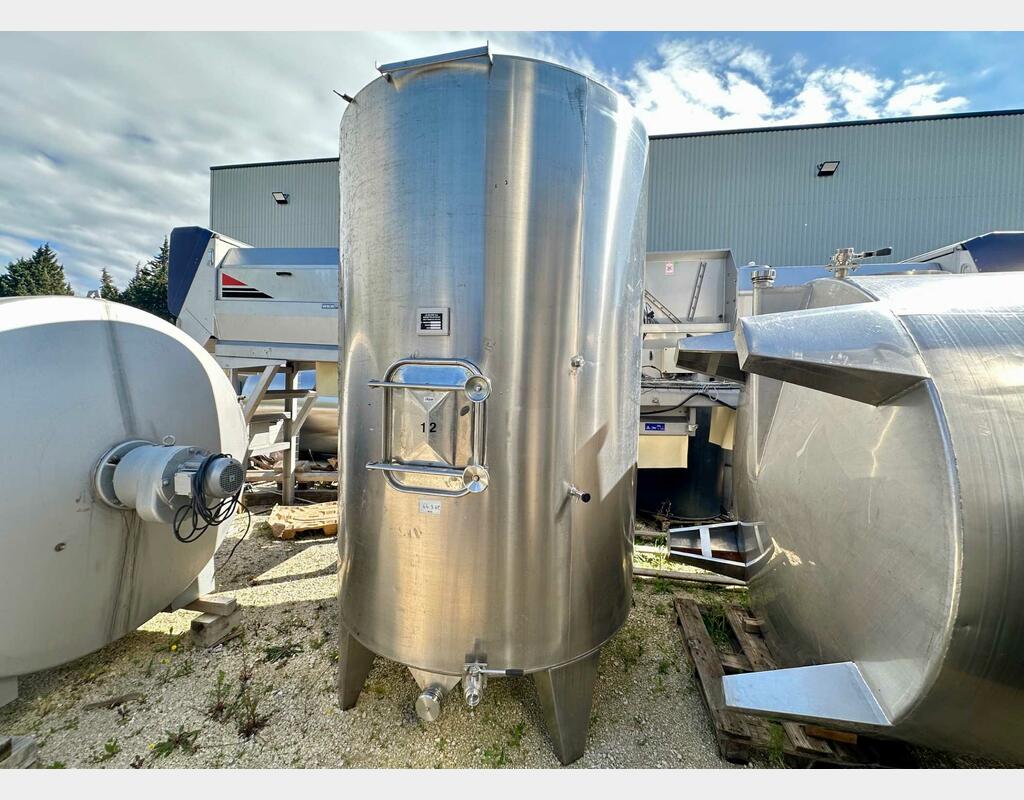

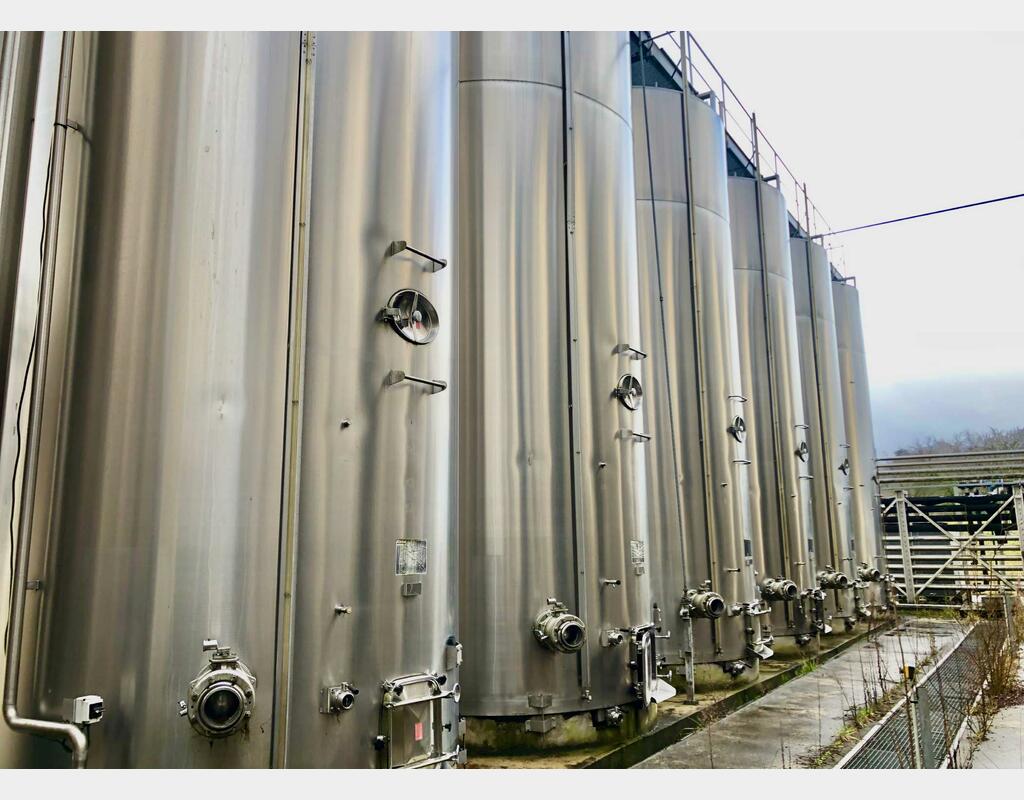

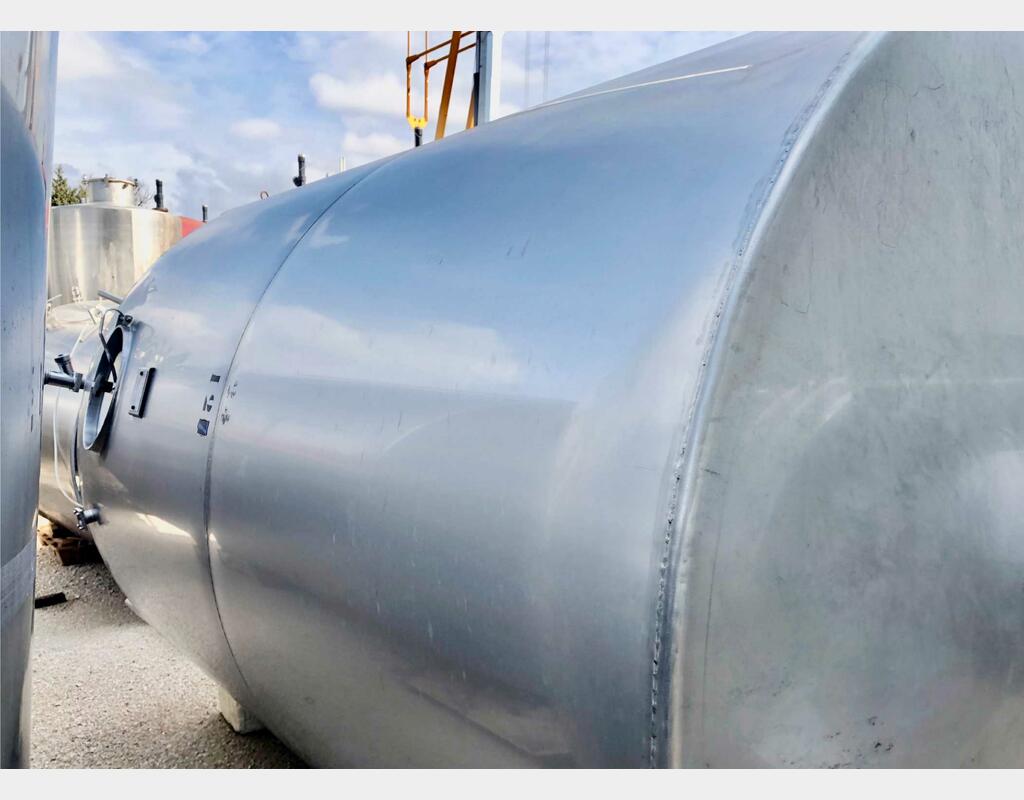

Wine storage : vinification tanks

• Stainless steel tanks for winemaking

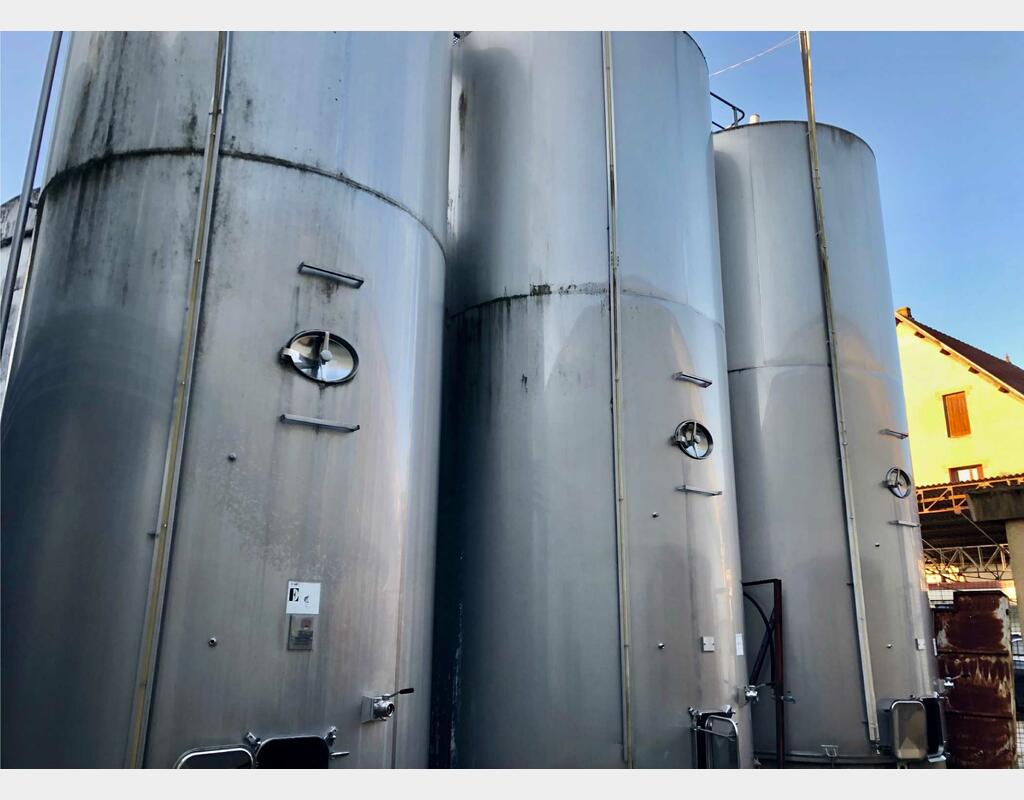

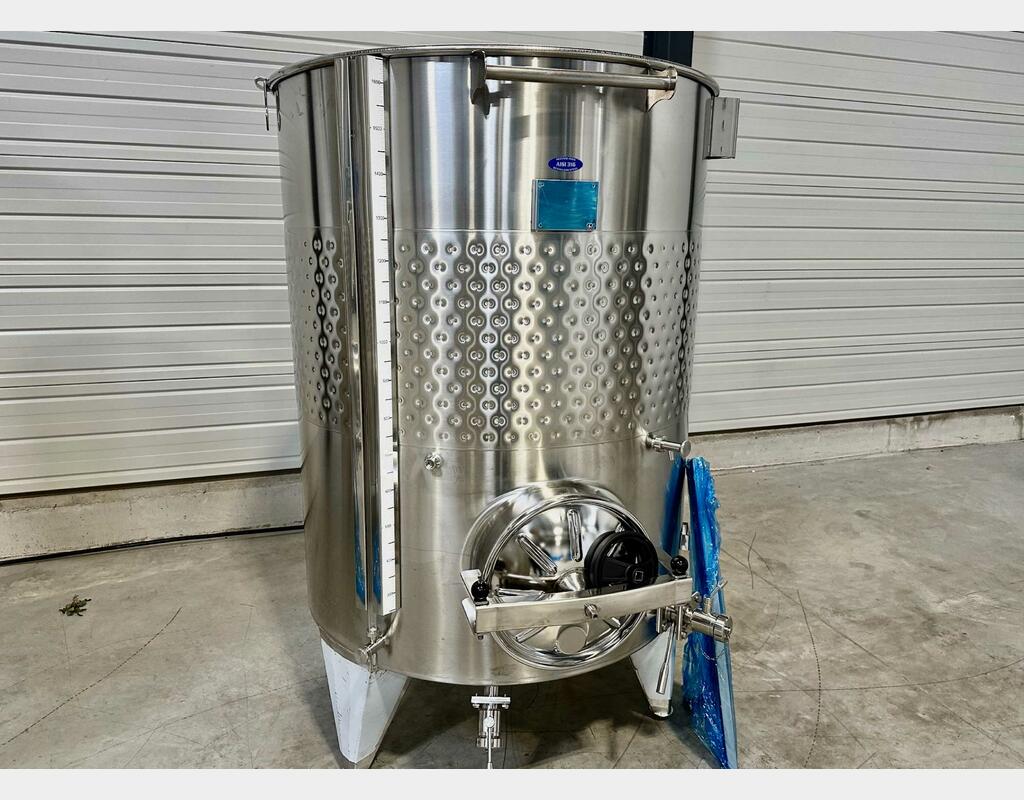

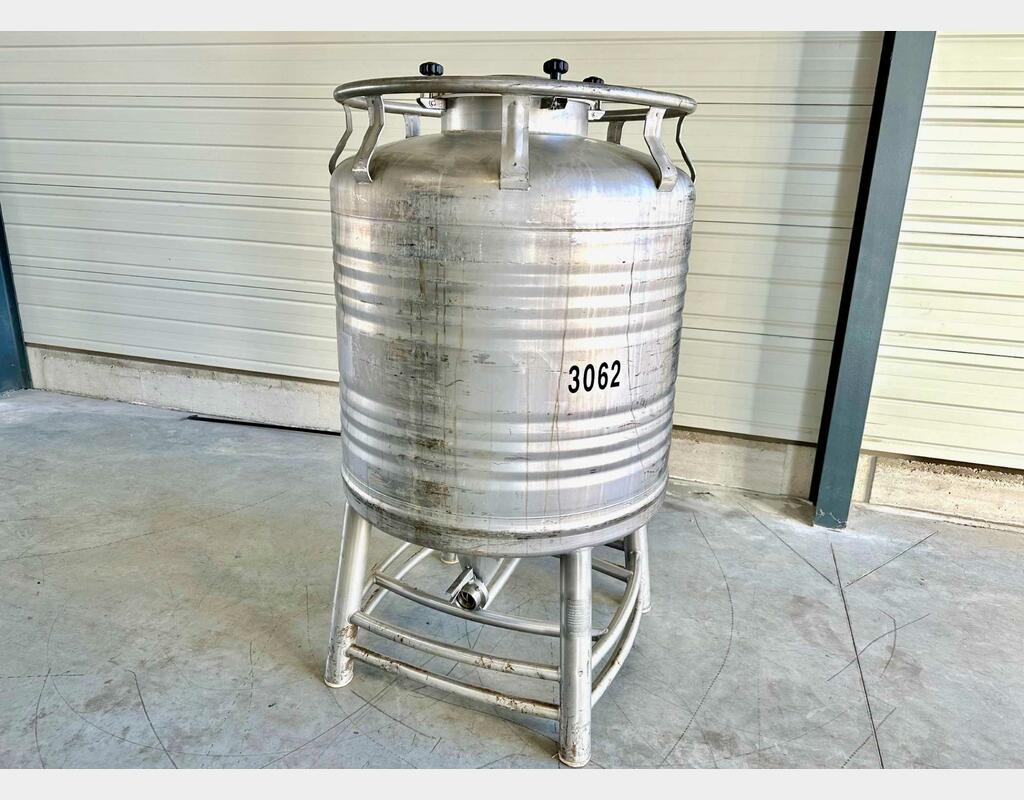

For ease of use and better risk management, stainless steel is one of the most widely used materials. Stainless steel is food-safe, easier to clean, lightweight and above all neutral in terms of taste and spillage. They can be stored either indoors or outdoors, and can incorporate a thermoregulation system via coils or flags. Stainless steel vats come in all sizes, making it possible to use small-capacity vats for plot-by-plot vinification projects.

Manufacture of a range of tank shapes, including yours.

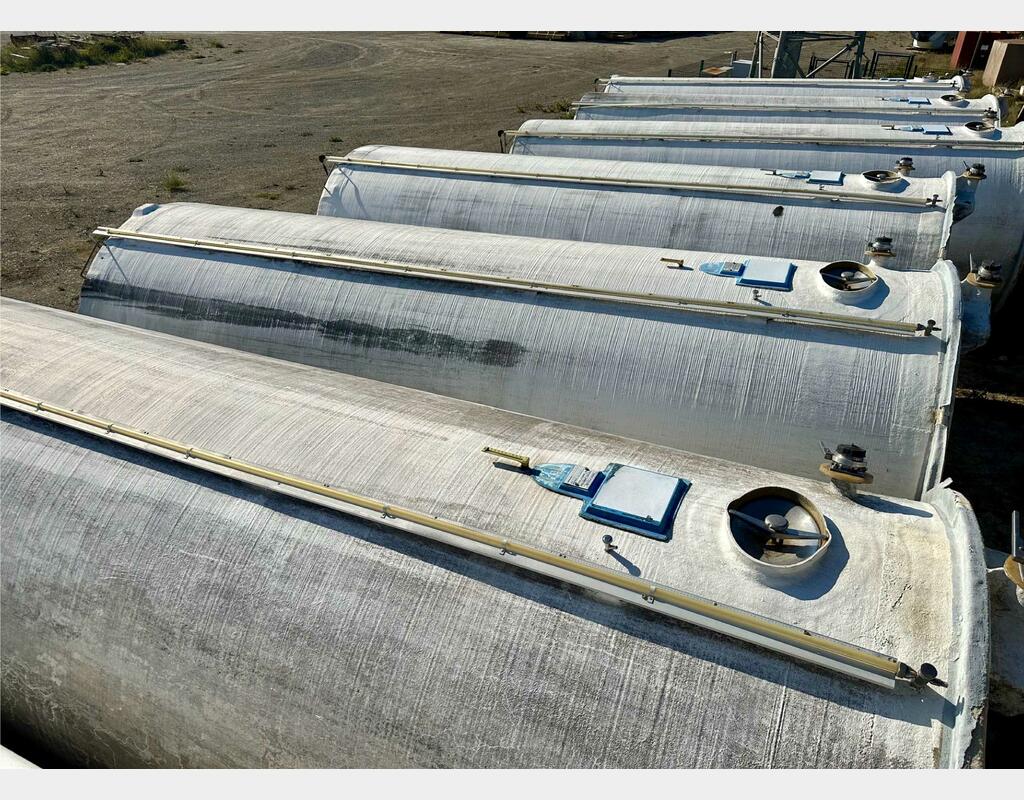

Vertical, horizontal, compartmentalised cylindrical tanks.

Vertical, horizontal, self-emptying truncated-cone tanks.

Tanks with movable ceiling, wine racks.

Parallelepiped tanks, quadrangular tanks, belons.

The design and manufacture of standard storage tanks to insulated truncated-cone tanks with heat exchangers and state-of-the-art equipment, the very height of winemaking technology.

We adapt to technical specifications, offering products tailored to your needs in terms of volume, shape, equipment and price.

→ Find out here about stainless steel wine tanks available in stock

• Self-emptying truncated-cone tanks

Function: maceration of fresh grapes, red vinification and wine storage.

Innovative product features: a vat with a truncated cone-shaped ferrule for natural punching down and improved crumbling of the marc during pumping over and bleeding. The combination of the truncated cone-shaped ferrule and an offset conical base allows automatic devatting. This innovation enables large producers to vinify in high-quality vats without disrupting the organisation of the winery.

• Insulated frustoconical tanks with heat exchange

Advantages :

- Natural punching down

- Better extraction of phenolic compounds

- Minimal heat loss

- Facilitates cold pre-fermentation maceration

- Even temperature thanks to good distribution of the peripheral heat exchanger

- Reduced energy consumption

- Ease of cleaning

- Aesthetics

→ Découvrir ici les cuves inox thermorégulées disponibles en stock

• Les gardes vins inox à chapeau flottants

Les garde vin sont construits suivant des process bien établis et qui ont faits leurs preuves au fil des années. Du garde vin simple avec ou sans porte, au garde vin avec échangeurs coquilles, au garde vin isolé, avec ou sans potence équipé de flotteur inox ou fibre suivant le choix du client, chacun pourra trouver le produit qui soit adapté à ces méthodes de stockage ou même de vinification.

→ Find out more about the temperature-controlled stainless steel tanks available from stock here

• Compartmentalised stainless steel tanks

From the 1-compartment vat, we can offer you vats with 2, 3 or 4 compartments for vinification or storage, or a mix of the two, allowing, for example, the upper vinification compartment to flow into the lower compartment by gravity, in all possible volumes and shapes.

→ Find out more about compartmentalized tanks

The wine presses

The principle of a wine press is to separate the juice or fermented wine (depending on whether it is red or white) from the skins, seeds and pulp that make up the solid parts of the grape. Unlike vertical presses, horizontal presses work by pressing the must or grapes from the inside (in the centre of the press) towards the outside. As a result, the whole batch of fruit receives the same pressure during pressing, so there's no need to choose between maximum yield and maximum quality. Continuous presses are quicker to operate per pressing cycle.

• Continuous pneumatic presses

The advantage of continuous presses is the 'continuous' sequence, which allows large volumes of grapes to be pressed with a minimum of work. Instead of pressing separate batches that have to be emptied and filled, continuous presses generally have an entry area and a mechanism (such as an auger or belt) that transfers the grapes through the presses with an exit area for rejected solids. Throughput is limited by the capacity of the tank and the diameter of the screw or width of the belts. Many models of continuous screw press can process from 50 to over 100 metric tonnes per hour. This can be a considerable advantage for a high-volume wine cellar compared with vertical presses, which often only process 1 to 5 tonnes per hour.→ Discover horizontal wine presses here

Specific peripheral equipment

- Piping, stairs, access walkways.

- Pumps, electro-technical installations

- Immersed multi-tube heat exchangers in stainless steel.

- Vertical and horizontal agitation systems.

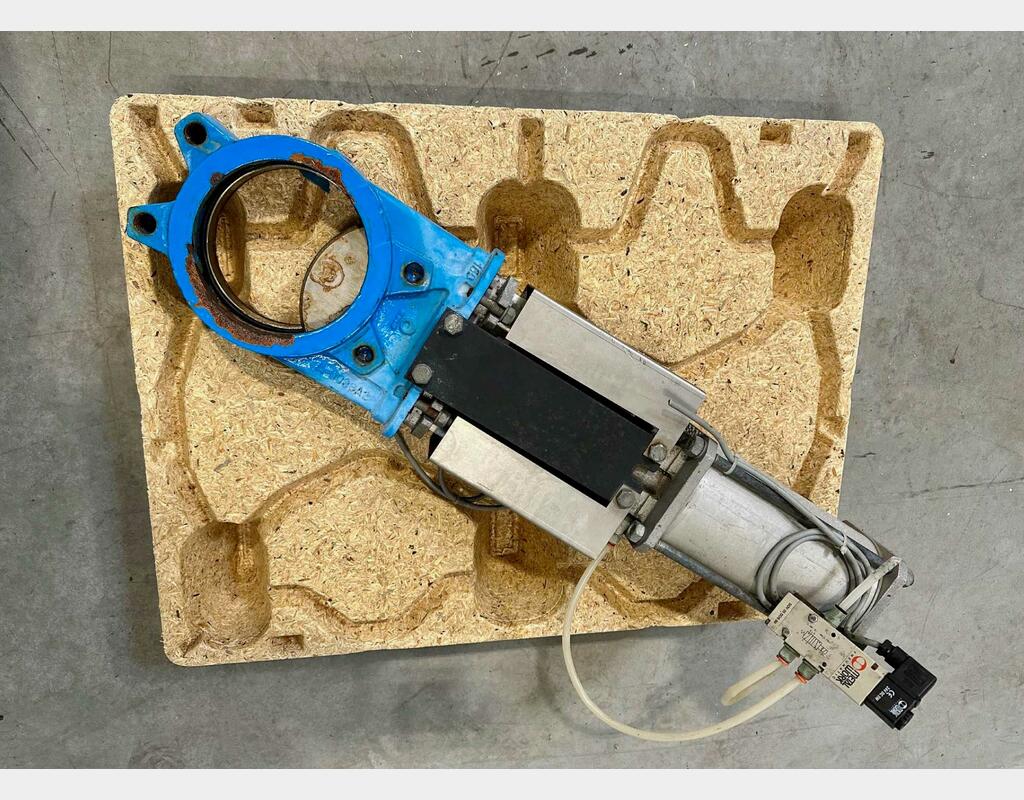

- Semi-automatic or automatic pneumatic pigging systems.

→ Find out here about peripheral equipment available in stock

Feedback from winemakers

→ Installation au Domaine des Chesnaies

→ FOCUS SUR ... le Domaine Les SIBU

→ Destination New York chez City Winery Hudson Valley !

→ FOCUS SUR ... le Domaine Luyton-Fleury

→ Installation au Domaine Fond Crozes

→ FOCUS SUR ... Le Domaine Guillaume Montfort

→ Livraison de cuves inox chez l'Ardent Winery

→ Installation de nouvelles cuves aux domaines vinicoles

→ Installation de cuves au Château de Ruth

→ Installations aux domaines vinicoles

→ Implantation de nouvelles cuves en acier inox

→ Installation au Domaine St Jean