How do I choose a valve for a stainless steel tank?

A practical guide to selecting the ideal valve

Stainless steel tanks play a central role in many industries, particularly in the food and pharmaceutical sectors, due to their ability to withstand corrosive environments and maintain the integrity of the fluids they contain. To ensure efficient fluid management, the choice of valve associated with these tanks is of particular importance. An unsuitable valve can lead to leakage problems, alter product quality or compromise the safety of production processes. This is why it is essential to select a valve taking into account technical parameters such as the nature of the fluid, the pressure applied and the specific requirements linked to operating conditions.

The characteristics of stainless steel

Stainless steel is widely used in the manufacture of tanks, valves and fittings in sectors such as food processing, chemicals and pharmaceuticals, because of its corrosion-resistant properties, robustness and hygienic qualities. These characteristics ensure a long service life for equipment while preserving the integrity of sensitive liquids. Among the most common alloys, type 304 and 316 stainless steels are distinguished by their specific composition, with 316 being particularly suited to more corrosive environments due to the addition of molybdenum. The ease with which these materials can be cleaned is also crucial in sectors where stringent health standards, such as those imposed by European regulations or the FDA, must be met.

|

Criteria for choosing a stainless steel tank valve

To choose the right valve for a stainless steel tank, a number of criteria need to be taken into account:

Type of fluid

The nature of the fluid is a decisive factor in choosing the right valve for a stainless steel tank. The specific characteristics of the fluid, such as its viscosity, chemical composition and the possible presence of solid particles, have a direct influence on valve selection. For example, a ball valve is often recommended for homogeneous, particle-free liquids, because of its ability to offer simple, rapid flow control. On the other hand, for more complex fluids or where precise flow adjustments are required, a poppet valve may be more appropriate. The choice of valve should also take into account additional factors such as the temperature and corrosivity of the fluid, to ensure optimum performance and long equipment life.

Pressure and temperature

In industrial environments, stainless steel valves must be able to withstand significant variations in pressure and temperature. Each valve has precise tolerances that determine its suitability for extreme conditions, from high pressures in pressurised fluid systems to high temperatures in thermal processes. Selecting valves with materials and designs that meet these requirements is essential to ensure long-lasting, safe performance. A thorough analysis of valve tolerances helps to minimise the risk of failure in critical applications.

Environmental conditions

In environments exposed to corrosive substances or requiring strict aseptic conditions, the choice of valve materials and design is of particular importance. Corrosion resistance, particularly in acidic or basic environments, is essential to preserve the integrity of fluid transfer systems and avoid premature damage. Furthermore, in sectors such as food processing or pharmaceutical production, aseptic stainless steel valves are preferred to guarantee an effective barrier against contamination. These valves, which comply with health standards, enable sterile conditions to be maintained throughout the production and storage processes, thereby reducing the risks associated with product safety.

The main types of valve for stainless steel tanks

There are different types of valves for stainless steel tanks, each with specific applications:

Ball valves

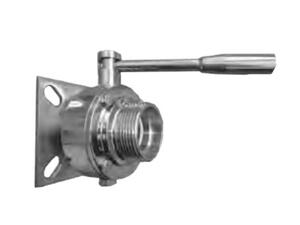

Ball valves, also known as ball valves, are widely used in industrial environments for their ability to provide precise and reliable control of fluid flow. Thanks to a simple ball rotation mechanism, these valves open and close the flow quickly, guaranteeing excellent tightness. They are particularly suitable for clean fluids such as water, gas or oil, but their robustness also makes them effective in environments with abrasive fluids. Their design facilitates maintenance and reduces wear, making them a durable and reliable option for applications requiring effective flow control without the need for complex regulation.

Stainless steel diaphragm valves

Stainless steel diaphragm valves are widely used in sectors where asepsis and sterility are paramount, such as bioprocessing and the management of corrosive fluids. Featuring a flexible diaphragm, these valves ensure complete separation between the fluid and mechanical components, eliminating the risk of cross-contamination. This mechanism is particularly advantageous in sterile environments, where the slightest alteration to the fluid could compromise the integrity of the process. In addition to their reliability in terms of sterility, these valves are designed to withstand extreme pressure and temperature conditions, making them indispensable in complex applications requiring maximum safety.

Stainless steel butterfly valves

Stainless steel butterfly valves are frequently used to control low-viscosity fluids because of their light weight and ergonomic design, making them easy to handle. Their compact design allows efficient installation in space-restricted environments, while minimising pressure drops, making them ideal for systems requiring energy optimisation. Particularly suited to the water treatment and chemical industries, these valves offer fast, reliable shut-off. Their corrosion resistance ensures durability in sometimes aggressive conditions, reducing maintenance costs and guaranteeing long-lasting performance.

Specific valves for the food and pharmaceutical industries

In the food and pharmaceutical sectors, preventing contamination and complying with hygiene standards are essential. Stainless steel aseptic valves play a crucial role in these environments by limiting the proliferation of micro-organisms, ensuring that product quality is maintained and regulatory requirements are met. Designed to operate under stringent conditions, these valves comply with international standards such as FDA and EU GMP, ensuring greater safety in production processes. In addition, the robustness and corrosion resistance of stainless steel make it a preferred material, contributing to the durability of installations and reducing the risk of cross-contamination.

The influence of connections and configuration on valve choice

The choice of valve connection affects not only compatibility with the vessel, but also the efficiency of cleaning processes, particularly in environments where hygiene is crucial. In the food industry, sanitary fittings are often preferred because of their ability to be easily dismantled and cleaned, making it easier to comply with strict hygiene standards. It is also important to consider whether a manual or automatic valve is preferable, depending on control and regulation requirements. This choice must take into account criteria such as the precision of the operation, the associated costs and the frequency of flow adjustment, thus enabling optimised management of industrial processes.

|

|

|

|

The choice of a valve suitable for a stainless steel vessel must be based on a rigorous assessment of the conditions of use, in particular the nature of the fluid, its viscosity, the pressure exerted and the operating temperatures. These factors directly influence the compatibility of the valve with the mechanical and chemical properties of the fluids concerned. In addition, the specific requirements of each industrial sector - from guaranteeing strict hygiene in the food industry to complying with sterility standards in the pharmaceutical sector - must be taken into account to avoid any risk of contamination or malfunction. It is advisable to call in an expert to assess the technical and regulatory specifics of each application, so as to optimise both the safety of operations and the durability of installations.

✖ Any doubts about the feasibility of your project?

Please do not hesitate to contact an Arsilac manager if you have any questions or would like more information on the types of valves used in industry. Find the valve solution that meets your needs.

_

Note: This article is for information purposes only and does not constitute professional advice. It is recommended that you consult experts and comply with the specific regulations of each industry.

#vannes #inox #Agroalimentaire #cuves #VannePapillon