SIAT case erector and turner - ITALPAL palletiser/returner - 007366

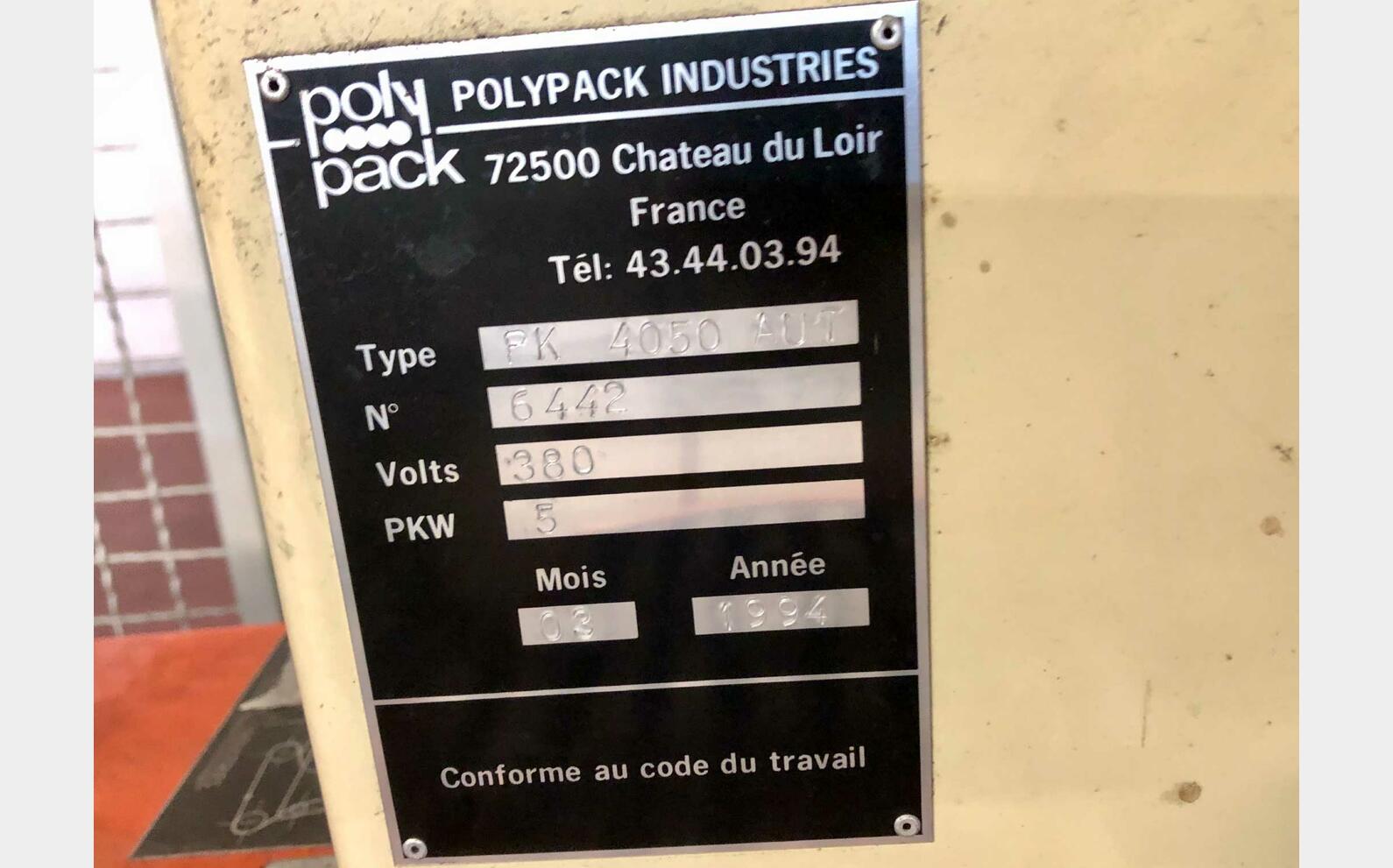

Stretch wrapper POLYPACK

Stock : 1

Detailed description :

TECHNICAL FEATURES

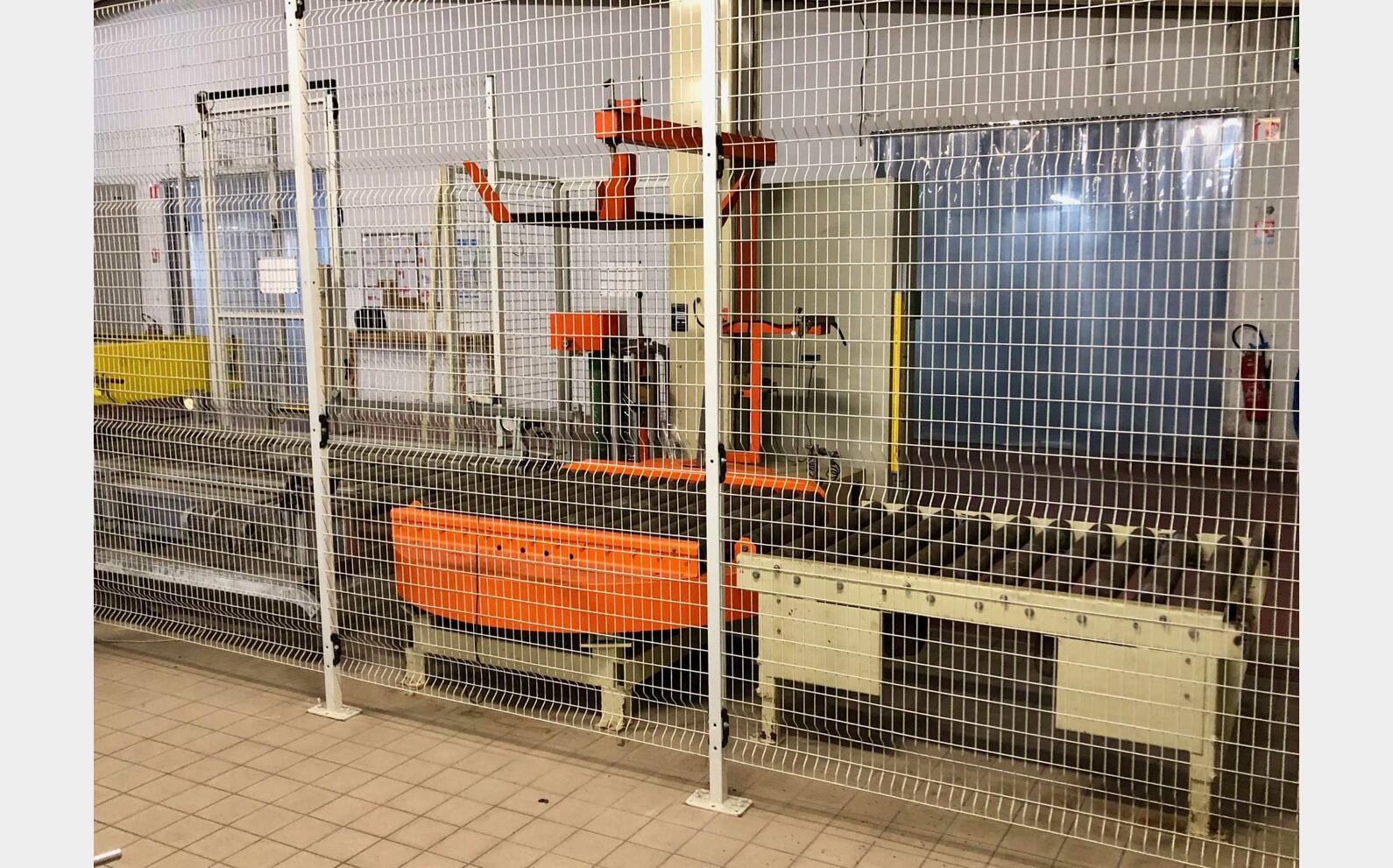

- Palletiser

- Brand : ITAL PAL

- Model : PS120R

TECHNICAL SPECIFICATIONS

-- Automatic palletising line for 6- or 12-bottle cartons (with output of 10 to 12,000 bottles per hour)

-- Cases of 6 bottles (2×3) or 12 (3×4)

-- Format: 230×150 mm and 280 mm high

-- Approximate weight: 6 kg

-- 1600 packs of 6 per hour or 1000 packs of 12 per hour

-- Pallets: 800×1200 mm and 1000×1200 mm

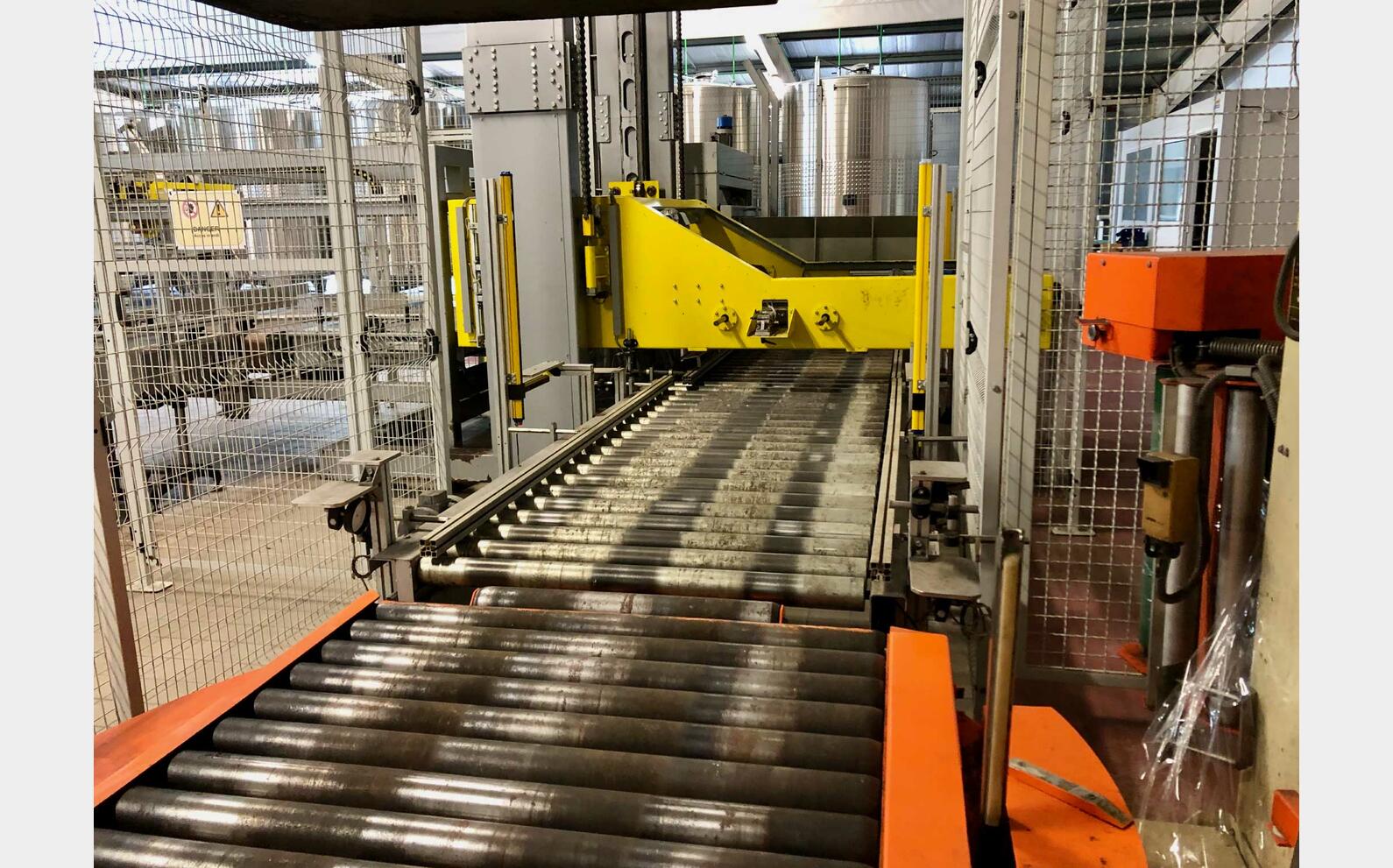

-- Empty and full pallets are moved on a motorised conveyor

-- An empty pallet magazine holds 10 pallets on standby

-- Cartons are turned upside down by a tipper

COMPOSITION

-- Infeed belt conveyor: consists of a belt conveyor on which the cartons arrive from the previous machine and are fed to the carton turner device, after which they are fed to the carton turner pusher unit.

-- Carton turner: this consists of an independent frame and a device that turns the cartons on the horizontal axis. This system consists of 2 belt conveyors and a turning unit. The cartons arrive on the belt conveyor, are turned over when the conveyor is full, and then leave for the carton turner-pusher unit.

-- Carton turner-pusher: the machine consists of a device for turning the carton on the vertical axis and a pusher that feeds the palletiser. The carton turner consists of a modular chain conveyor and a pivot for rotating the carton. The pusher consists of an independent frame and a unit that forms the layer of products to be sent to the palletiser. When the layer of products is completely formed, it is pushed towards the head of the palletiser.

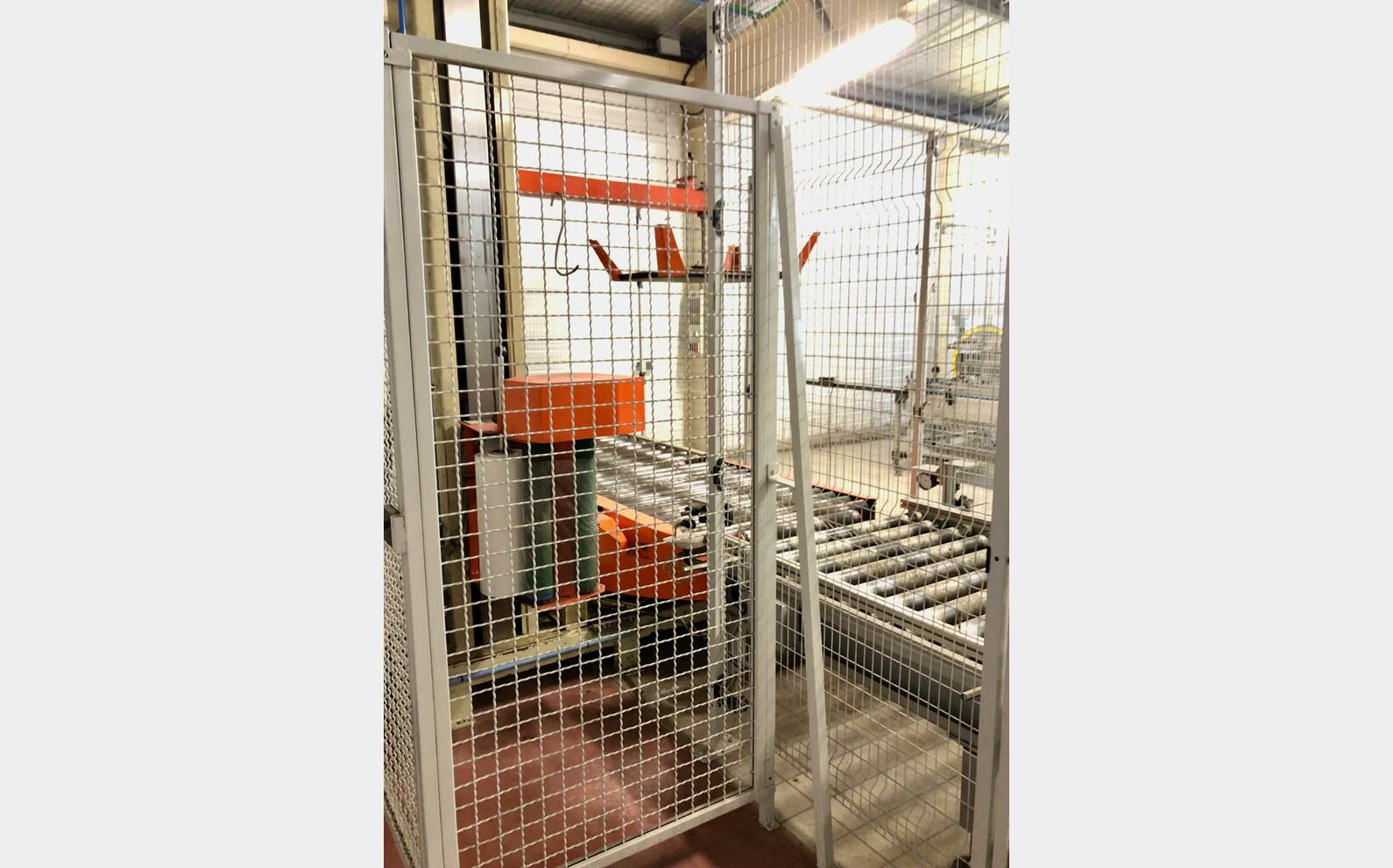

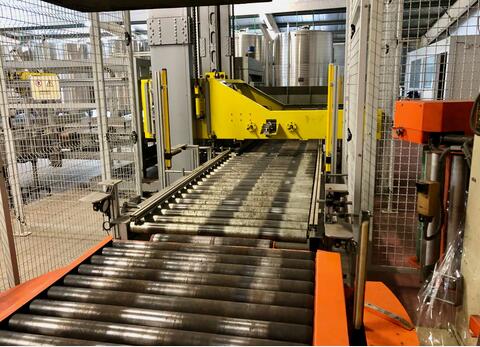

-- Palletiser: The machine consists of a frame, a carriage for vertical movement, a gripper head with axial movement and an intermediate roller table for transferring the layers of products to the pallet. The layer of products fed by the pusher is blocked by the head's shovels, transferred to the intermediate roller table and finally deposited on the pallet.

-- Pallet magazine: the pallet magazine consists of two mobile shovels which hold the empty pallets and feed them to the conveyor one at a time. The empty pallets are carried to the pallet magazine by a forklift truck and the magazine feeds the pallet to be filled by the palletiser.

-- Roller conveyor: the roller conveyor transfers the empty pallet below the palletiser head, positioning the pallet in the palletising position. When the pallet is full, the roller conveyor transfers it to the line exit towards the rewinder.

-- Pneumatic system: The pneumatic system comprises a tank and a series of solenoid valves and pistons for handling the various devices.

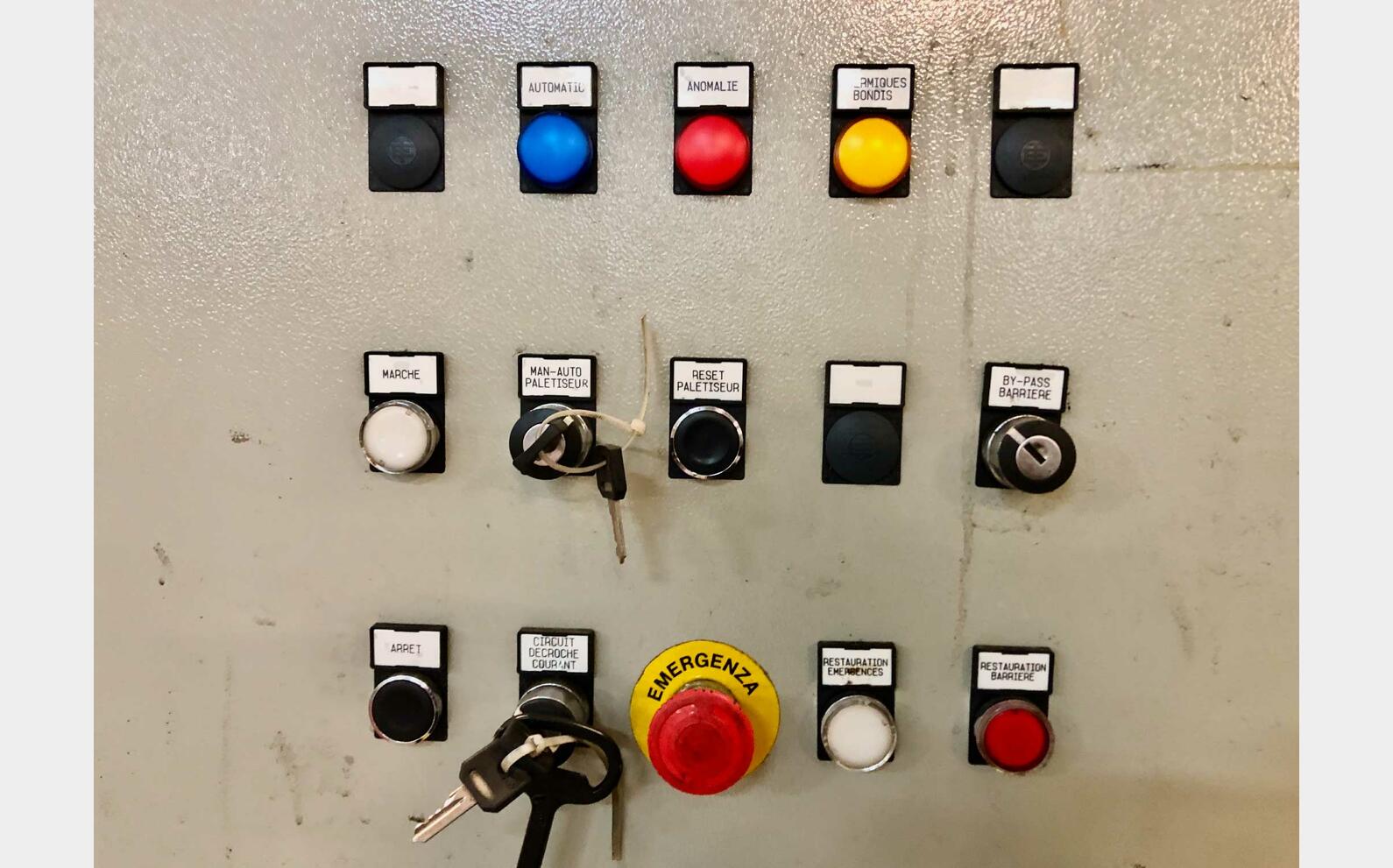

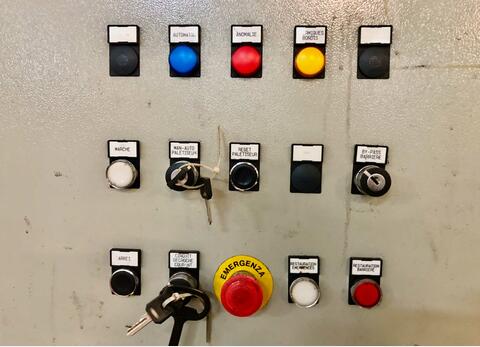

-- General electrical panel: the general electrical panel is housed in a cabinet normally located against the machine's perimeter protection in the outer part. It is supplied complete with operator panel, buttons and indicators for machine operation.

DIMENSIONS

- On going redaction

ANNEXES

- Complies with CE standards

_________________

TIPS AND NEWS

- Used bottling machines

Find out more about the benefits of upgrading in this article.