Temperature control solutions for stainless steel tanks - Food industry

Temperature control systems in the food industry

In the food industry, and particularly in wine production, temperature control is a key success factor. Whether for fermentation, stabilisation or preservation, precise temperature control guarantees the quality, energy efficiency and consistency of the processes. Thanks to their adaptability and thermoregulation solutions, stainless steel tanks have become essential for meeting the specific needs of professionals.

This article explores the best temperature control solutions for stainless steel tanks, with a particular focus on applications in wine production.

The importance of temperature control in industry

Precise temperature control is extremely important in food processing. Temperature influences virtually all the biological, physical and chemical processes that take place during food processing and determine the properties of the final product. By controlling the temperature precisely, the user can actively intervene in the processes, regulating and directing them as desired. Proper temperature control makes processes energy-efficient and cost-effective.

For effective thermoregulation, professionals must take into account :

- Use of the tank : fermentation, storage, stabilisation.

- Minimum and maximum temperatures required.

- Environmental conditions (ambient temperature).

Technical temperature control solutions for stainless steel tanks

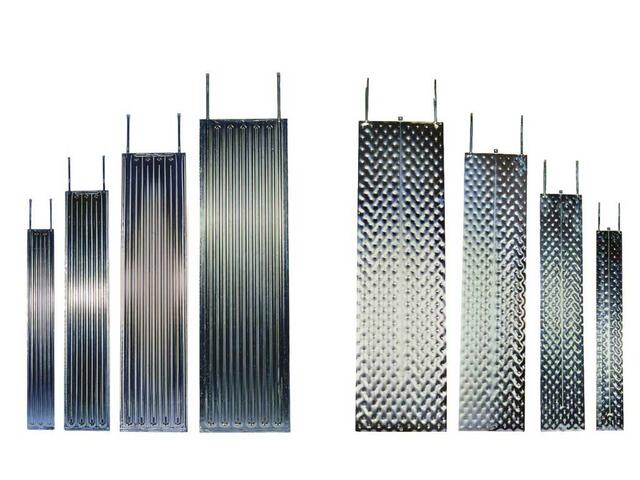

Stainless steel flag or heat exchanger plates

These plates can be installed in vertical, horizontal, cylindrical, rectangular or oval tanks. As the plate is in direct contact with the product in the tank, this cooling/heating system is highly efficient.

The plates are made of AISI 304 or 316 stainless steel. The smooth electropolished surface prevents deposits, such as scale, from forming on the plate. The cooling fluid can be water or glycol.

Advantages of stainless steel tanks with flag :

- High thermal efficiency.

- Smooth surface limits scale deposits.

- Adaptable to various types of tanks (vertical, horizontal).

Stainless steel cooling coil

The serpentine heat exchanger consists of a long, small-diameter tube wound around itself. It is used to circulate a hot or cold liquid and offers an excellent exchange coefficient. The coil is widely used to regulate temperature during treatment. It is immersed in the liquid and operates without any thermal bridge to the outside, without thermal shock and without any mechanical effect that could affect the quality of the final product. The coil principle allows the liquid to circulate at high speed to maximise the heat exchange coefficient.

Advantages of stainless steel tanks with coils :

- High heat exchange coefficient.

- Direct immersion in the product for precise control.

- No thermal bridges, preserving product quality.

Honeycomb or double-walled stainless steel circuit

The double casing consists of two sheets of sheet metal, laser-welded together and then inflated under pressure. The result is a curved profile on one side through which the cooling or heating fluid flows. Double-jacketed tanks are ideal for use in the food industry, as well as in other sectors where processes depend on temperature, such as wine production, brewing, juice and dairy production, etc.

Advantages of stainless steel tanks with honeycomb circuit :

- Suitable for all food applications (juice, dairy, wine).

- Even heating or cooling.

- Easy maintenance.

Coil circuit or cold belt

Welded to the cylindrical outer casing, the spiral is curved outwards and forms an intermediate space with the container casing, in which the cooling fluid circulates and acts on the product temperature. The pressure difference required between the inlet and outlet of the coil is determined by the cooling fluid, the length of the spiral and the desired fluid flow rate.

Advantages of stainless steel tanks with coil circuit :

- Suitable for large tanks.

- Effective for rapid cooling.

Practical applications for wine production

Cooling the fermenting must during vinification is permitted in order to prevent its temperature from rising beyond the acceptable technological limits. Cooling is therefore an authorised and important process in modern winemaking.

Cooling the fermenting must

The process can begin by cooling the must. We know that an excessive rise in temperature can halt fermentation (by inhibition or death of the yeasts). The vats must therefore be cooled. Cooling is also essential to preserve freshness and fruitiness, particularly in white and rosé wines. These wines are generally vinified at low temperature, between 16°C and 20°C. Red wines ferment at a higher temperature (between 28°C and 30°C). Above these temperatures, the risk is that fermentation will stop, but also, for white and rosé wines, a reduction in aromatic richness and a change in colour; for red wines, a change in bouquet and the appearance of a bitter or herbaceous taste.

Cold stabilisation for wine conservation

Cooling helps to preserve the wine in the vats. Stainless steel vats often have a double-walled system that allows water to circulate. To stabilise the wine and prevent the appearance of tartar in the bottle, cold stabilisation is the necessary operation. This technique, which also helps to stabilise the colour of red wines, involves lowering the temperature of the wine to -4°C for one (for white wines) to several weeks (for red wines). At the end of this period, the wine must be filtered (always cold).

How do I choose the right temperature control system ?

To select the system best suited to your needs, consider the following criteria :

- Use of the tank : fermentation, stabilisation, storage.

- Required temperature : temperature range and control speed.

- Type of product : white, red and rosé wines, specific food products.

- Environmental conditions: ambient temperature in the production area.

The temperature control of stainless steel tanks is an essential element in guaranteeing the efficiency and quality of food and wine processes. Technical solutions such as heat exchanger plates, coils, stainless steel double walls and cooling belts offer solutions tailored to the specific needs of professionals.

✖ Any doubts about the feasibility of your project?

Don't hesitate to contact an Arsilac manager if you have any questions or would like more information about the temperature control solutions best suited to your needs.

FAQ

Q1 : How does temperature control work in stainless steel tanks ?

The temperature control of stainless steel tanks relies on ingenious systems to precisely control the temperature of the liquids contained. The most common solutions include cooling coils, integrated directly into the tank, or heat exchanger plates for effective thermal regulation. For more advanced tanks, a stainless steel double wall can be used, often combined with a cooling belt. These systems ensure optimum temperature management, avoiding variations that can affect product quality, particularly during the winemaking or cold stabilisation processes.

Q2 : Why is it important to control temperature during vinification ?

Temperature control during winemaking is essential to ensure optimal fermentation and preserve the quality of the wine. Too high a temperature can accelerate fermentation, altering the aromas and structure of the wine, while too low a temperature can slow or stop the process. Thanks to vat temperature control systems, such as cooling coils or heat exchanger plates, producers can control the temperature for a precise winemaking process. This management improves wine conservation while ensuring controlled fermentation techniques.

Q3 : How do I install a temperature control system on a stainless steel tank ?

Installing a temperature control system on a stainless steel tank involves several key stages. Firstly, it is crucial to choose the right equipment: a cooling coil or heat exchanger plates for internal temperature control. The next step is to connect these devices to an automated temperature control system that monitors and adjusts the temperature in real time. Finally, a check of the system's tightness and settings ensures optimum performance for processes such as fermentation or cold stabilisation.

_

Note: This article is for information purposes only and does not constitute professional advice. It is recommended that you consult experts and comply with the specific regulations of each industry.

#industrie #agroalimentaire #cuve #thermoregulation #temperature #serpentin #drapeau #circuit