Guide to installing a floating cap on stainless steel tanks

Optimising the installation of mobile ceilings on stainless steel tanks

Installing a floating cap on a stainless steel tank is a crucial step in optimising the storage and fermentation of wines and other beverages. This detailed guide will show you the steps involved in installing a floating cap on a stainless steel tank, as well as the best practices for ensuring that it works properly.

Floating top wine tanks transform tanks into containers of variable capacity for fermentation as well as short- and long-term storage of wines and beverages. This type of mobile ceiling tank is mainly used for red and white winemaking in the wine industry, but it is also used in many other sectors of the food industry.

Although this example uses a stainless steel tank, the system also works with other types of tanks, such as fibreglass resins. The lid is simply inserted inside the tank and allowed to float on the surface of the product. An air chamber around the lid is inflated to create an airtight seal. Here are Arsilac's tips and advice for installing a floating cap on a stainless steel tank for vinification or wine maceration.

Why choose a floating cap system for stainless steel tanks?

The floating cap system for stainless steel tanks is widely used in the wine and food industries. It works on a simple but effective principle: the floating cap is inserted inside the tank and floats on the surface of the liquid, creating a watertight barrier thanks to an inflatable air chamber. This solution offers a number of advantages:

- Variable capacity for fermentation and storage

- Reduced contact with air, limiting oxidation

- Preservation of product quality in the short and long term

Floats, two types of floating hats

There are two types of float on which you can fit an inner tube.

|

The ‘moulded’ pneumatic float • From Ø 380 to 2070 • Available with tie rods • Available with PVC vent valve |

|

‘Welded’ pneumatic float • From Ø 2190 to 2550 • Available with tie rods • Available with PVC vent valve |

The choice between a moulded and a welded pneumatic float depends mainly on the size of your vats and your specific winemaking requirements. For small and medium-sized vats, moulded floats offer superior robustness and reliability without the weak points of welds. On the other hand, for large vats, welded floats are necessary to achieve the required dimensions, despite potentially more demanding maintenance.

Steps for installing a floating cap on a stainless steel tank

A floating cap, by allowing the level of liquid in the vat to be monitored and minimising contact with the air, plays an essential role in preventing oxidation and preserving the quality of the wine. This process requires careful attention to detail and the use of specific tools to ensure a perfect seal.

Fitting the inner tube to the float

Two operators are needed to fit the inner tube to the floating caps.

▲ WARNING

It is important to use the necessary PPE.

|

|

|

|

|

|

|

Operator 1-2 : Once the inner tube is inserted at least halfway up the float, pull it until it is completely recessed. |

Fitting the stem

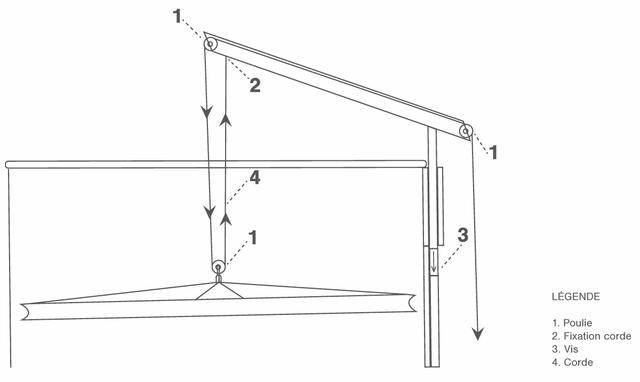

Pulley required from diameter 1800

Installing the tank before fitting the movable ceiling

Avant de pouvoir faire monter le chapeau flottant, il est nécessaire d'intégrer les éléments suivants sur la cuve :

- the winch

- the pump

- the gallows

Fitting and installing the float in a stainless steel tank

Please follow these instructions carefully :

|

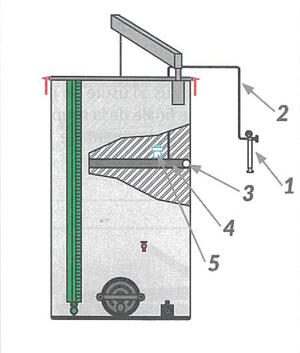

• Filling the mobile ceiling tank ; • Place the float (4) with the air chamber (3) and the PVC aeration valve (5) on the surface of the wine; • Inflate the inner tube using the pump supplied (1) to a pressure of approximately 7 atm ; • Check that the inner tube inflates evenly and that it seals perfectly along the entire length of the tank wall. |

Use the pulley to lift the float above the tank and lower it slowly into the tank. Be particularly careful and never stay below the float as shown in figure 2 on the left. Always use PPE and take great care.

▲ WARNING

If the pressure in the inner tube is not sufficient, check :

• There are no holes;

• There are no leaks between the inner tube and the hose;

• That the hose clamps are tight;

• That the pressure gauge is working properly;

• That the pump flywheel is tight.

CARRY OUT THESE CHECKS OFTEN TO AVOID ACCIDENTS

|

|

|

The importance of pump overhaul

|

O-rings or pump seals should be cleaned or greased with edible oil or Vaseline grease every 6 months. If they are consumed, broken or otherwise damaged, they must be replaced immediately. Malfunctions are normally due to wear of the O-ring on the final part of the air intake and exhaust valve. |

|

They must be replaced when consumed. |

Installing a floating cap on a stainless steel vat is an essential operation to guarantee the quality and longevity of your wine. By following the detailed steps, from preparing the vat to checking that it is watertight, you can ensure optimum protection against oxidation and contamination.

Regular maintenance and constant monitoring of the seal are crucial to maintaining the efficiency of the floating cap. Correct installation and regular maintenance will not only preserve the quality of the wine, but also ensure the durability of your equipment.

In conclusion, attention to detail and following best practice in installation and maintenance will enable you to get the most out of your floating cap and stainless steel tanks. This rigorous, professional approach is the key to successful winemaking and high-quality wine production.

Do not hesitate to contact Arsilac to discuss your project and define the equipment best suited to your production or operating constraints.

#chapeaufottant #montage #plafondmobile #cuve