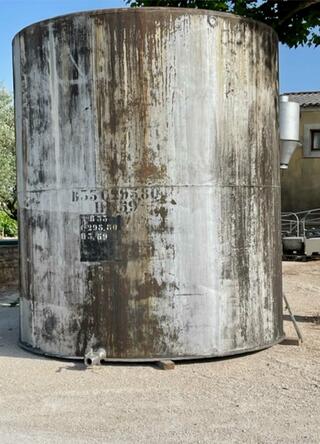

Corrosion and rust in stainless steel tanks

Causes and solutions for pitting corrosion

Stainless steel tanks are indispensable equipment in demanding sectors such as food, chemical and beverage production, where reliability and hygiene are paramount. However, such equipment is exposed to threats such as pitting and rusting, often caused by agents such as chloride ions. These phenomena lead to economic losses, business interruptions, and deterioration in product quality. Fortunately, proven solutions exist to combat these problems: passivation, a method that restores stainless steel's protective layer, and regular maintenance are at the heart of these strategies. In this article, explore the root causes of stainless steel corrosion and discover practical, effective methods for protecting your equipment, maximizing efficiency and extending service life.

Understanding pitting and rusting

What is pitting corrosion ?

Pitting corrosion is a form of localized degradation that affects stainless steel vessels, causing small holes or cavities in the metal surface. This phenomenon generally occurs when chloride ions are present in the environment, as in salt solutions or certain chemicals used in the food industry. Unlike generalized corrosion, which affects a surface uniformly, pitting corrosion attacks specific points in depth, rapidly compromising the integrity of the material. In this article, we explain the chemical mechanisms behind this phenomenon and how you can protect your equipment.

• Definition and chemical mechanism

Pitting corrosion results from an electrochemical process in which the passive protective layer of stainless steel is compromised. Normally, this thin oxide layer protects the metal against corrosive agents. However, in the presence of chloride ions, it can be destroyed, exposing the raw material to the corrosive environment. This localized reaction is amplified by micro-defects on the metal surface, accelerating degradation in specific areas. Understanding this mechanism is essential to adopting effective solutions such as passivation and regular maintenance.

• Difference with other forms of corrosion (generalized vs. localized)

Pitting corrosion differs from generalized forms in its discreet yet dangerous nature. Whereas generalized corrosion affects a large surface area uniformly, making signs visible sooner, localized corrosion concentrates on specific points, often difficult to detect with the naked eye. This can rapidly compromise stainless steel vessels, especially in environments where aggressive substances such as chlorides are present. These distinctions underline the importance of preventive techniques such as passivation and proper maintenance.

Conditions necessary for corrosion: surface defects, imperfect passivation, etc.

Although stainless steel is designed to resist corrosion, certain factors can lead to the appearance of rust on stainless steel tanks. Surface defects, such as scratches or contaminating deposits, disrupt the protective passive layer. Similarly, imperfect or non-existent passivation makes the metal vulnerable to corrosive agents, notably chloride ions. These conditions are exacerbated by humid environments or high temperatures, often encountered in the food or chemical industries. By understanding these causes, you can implement appropriate preventive strategies to extend the life of your tanks.

Main causes of corrosion in stainless steel tanks

Influence of chloride ions

• Origin of chlorides (water, cleaning, salt)

The presence of chloride ions is one of the main causes of pitting corrosion in stainless steel tanks. These aggressive particles can come from a number of common sources: the water used in industrial processes, especially if it is rich in mineral salts; cleaning products, often formulated with chlorine compounds; or salt deposits from stored raw materials. These sometimes invisible sources are a constant threat to the passive layer of tanks. Identifying these sources enables you to better adapt your cleaning and maintenance practices to protect your equipment.

• Catalytic effect on pitting corrosion

Once present, chloride ions trigger a specific chemical reaction that weakens the protective oxide layer on the surface of stainless steel tanks. This process, known as corrosion catalysis, creates microscopic rupture points where the underlying steel is exposed. This micro-damage develops into deep pitting over time, threatening the structure of your tanks. Once set in motion, pitting corrosion is difficult to stop, making it a problem to keep a close eye on.

Environmental factors : Humidity, temperature, pollution

The direct environment of stainless steel tanks has a major influence on their resistance to rust and localized corrosion. High humidity promotes condensation and creates areas where water stagnates, increasing the concentration of corrosive elements such as chloride ions. Temperature variations also accelerate chemical reactions; for example, rapid cooling of a vessel after a thermal process can create micro-cracks conducive to moisture ingress. Air pollution, particularly in industrial areas, adds a further layer of risk. Acidic particles and gases, such as sulfur dioxide, interact with stainless steel and amplify degradation.

Defects or damage to the passive layer : Scratches, mechanical impact, aggressive chemicals

The passive layer of stainless steel is a thin film of chromium oxide that forms naturally on the surface, offering remarkable resistance to corrosion. However, this barrier can be easily compromised by scratches, often caused by tools or friction during installation or tank handling. Even minor mechanical shocks are enough to create weak points where corrosion can start. What's more, certain aggressive chemicals used for cleaning or disinfection can damage this protective layer, leaving the metal bare and vulnerable. Rigorous maintenance and appropriate techniques, such as the use of non-abrasive products, are essential to limit these risks.

Impact of corrosion on stainless steel tanks

Reduced tank life

Pitting corrosion on stainless steel tanks can considerably reduce their lifespan, threatening industrial infrastructures. These areas of localized corrosion, often due to the influence of chlorides on stainless steel, compromise the strength and robustness of the material. As a result, cracks or perforations may appear, requiring frequent repairs or, in the worst case, complete tank replacement. However, solutions such as stainless steel passivation and regular maintenance help to protect tanks from these aggressions, ensuring optimum durability.

Risks to the quality of stored products

Corrosion of stainless steel tanks is more than just an aesthetic problem: it can affect the quality of stored products, particularly in the food and beverage industries. Rust particles or corrosion deposits can contaminate liquids or foodstuffs, compromising their purity and compliance with food safety standards. Preventing such contamination requires rigorous tank maintenance and the application of protective techniques such as passivation, which reinforces the passive layer of stainless steel and prevents rust formation.

Repair and replacement costs

Pitting corrosion and rust on stainless steel tanks are a major cost factor for companies. Between the cost of repeated repairs, premature equipment replacement and losses due to production interruptions, expenses can quickly mount up. What's more, indirect costs such as reputational damage or regulatory sanctions can add to the bottom line. By adopting preventive solutions such as passivation and appropriate maintenance, it is possible to extend the life of tanks while reducing unforeseen expenses.

Prevent corrosion

Passivation techniques

The passivation technique, a real ally against pitting corrosion, is a chemical process designed to reinforce the natural passive layer formed on stainless steel tanks. This protective layer limits interaction between stainless steel and corrosive elements such as chloride ions. For maximum effectiveness, we recommend using suitable solutions containing mild acids, such as nitric acid, and carrying out this operation at a frequency suited to your operating conditions. Regular passivation, combined with meticulous monitoring, ensures long-lasting protection and minimizes the risk of localized corrosion.

Regular maintenance of stainless steel tanks

Regular maintenance of stainless steel tanks is a key factor in preventing pitting corrosion and maintaining their performance. Proper cleaning must remove deposits and contaminants without altering the passive protective layer. Opt for non-abrasive products specially formulated for stainless surfaces, and avoid agents containing chlorine or abrasive particles, which promote rust formation. By adopting these best practices, you'll protect your equipment against localized corrosion and ensure its longevity.

Monitoring operating conditions

Monitoring operating conditions is essential to prevent corrosive attack on stainless steel tanks. Excessive chloride levels, often present in water or stored products, are one of the main triggers of pitting corrosion. Make sure you maintain acceptable levels with regular analyses. Similarly, monitor and regulate temperature and humidity in operating environments. Extreme variations can weaken the passive layer and accelerate degradation. With rigorous monitoring, you can anticipate problems and protect your equipment over the long term.

Rust removal methods

Chemical treatments

To effectively treat rust on stainless steel tanks, chemical treatments are often preferred. Citric acid and phosphoric acid, for example, offer a gentle but effective solution for dissolving pitting corrosion. These acids have the advantage of not being as aggressive as other chemicals, thus reducing the risk of stainless steel deterioration. What's more, they integrate perfectly into periodic maintenance processes to extend equipment life. By using these products, engineers and equipment managers can eliminate rust while preserving the integrity of their tanks.

Mechanical cleaning

Mechanical cleaning is a robust method of removing rust from stainless steel tanks, particularly where corrosion is stubborn. Techniques such as electrolytic polishing not only remove impurities, but also create a smoother, corrosion-resistant surface. Shot-blasting, on the other hand, is an ideal solution for treating large surfaces quickly and evenly. These mechanical methods ensure complete rust removal while preparing tanks for subsequent preventive treatments. Beverage producers and fluid managers will find these solutions particularly effective in meeting their demanding industrial needs.

Preparation after rust removal

Once the rust has been eliminated, re-passivation becomes an essential step in guaranteeing the durability of stainless steel tanks. This process involves applying a chemical treatment, often acid-based, to reform the protective chromium oxide layer on the stainless steel surface. This step is essential to restore corrosion resistance, particularly in environments rich in chloride ions, often responsible for pitting corrosion. Ignoring this phase could compromise the effectiveness of previous maintenance efforts and expose tanks to further corrosive attack.

Pitting and rusting on stainless steel vessels represent major challenges for industry professionals. Understanding the causes, such as exposure to chloride ions and alteration of the passive layer, is essential to prevent these degradations. The impact of these phenomena is not limited to material costs alone: it can compromise product quality and continuity of operations. By adopting regular maintenance practices and implementing proven techniques such as passivation, you can extend the life of your equipment while preserving its performance. Don't let corrosion become an obstacle - act today to protect your stainless steel tanks.

FAQ

Q1 : How can I prevent pitting corrosion on stainless steel tanks ?

Pitting corrosion is a localized phenomenon that can affect the durability of stainless steel tanks, especially in the presence of chlorides. To prevent it, it's essential to choose quality stainless steel, such as high-molybdenum alloys, which are more resistant to chemical attack. Passivation of stainless steel is a key method: it consists in reinforcing the natural passive layer on the surface, thus reducing vulnerability to corrosion. In addition, regular maintenance of stainless steel tanks is crucial to remove deposits and contaminants.

Q2 : What are effective methods for removing rust from stainless steel tanks ?

There are several possible solutions for removing rust from stainless steel tanks. The use of specific chemical products, such as mild acid strippers, effectively removes traces of corrosion without damaging the steel. After this treatment, passivation is recommended to re-form the protective layer. Mechanical techniques, such as polishing or soft sandblasting, can also be used for heavily affected areas. Finally, adopting preventive cleaning practices, such as using chloride-free water, limits future risks.

Q3 : What impact do chloride ions have on the corrosion of stainless steel tanks ?

Chloride ions are one of the main causes of localized corrosion on stainless steel tanks. They destroy the passive layer that protects stainless steel, causing deep pitting that is difficult to detect at first glance. These attacks are particularly frequent in humid or saline environments. To minimize their impact, it is advisable to opt for specific alloys, such as 316L stainless steel, and to maintain optimal storage conditions. Rigorous maintenance and regular analysis of the quality of stored fluids also help prevent damage.

_

Note: This article is for information purposes only and does not constitute professional advice. It is recommended that you consult experts and comply with industry-specific regulations.

#inox #corrosion #acierinoxydable hashtag #passivation #entretien #rouille