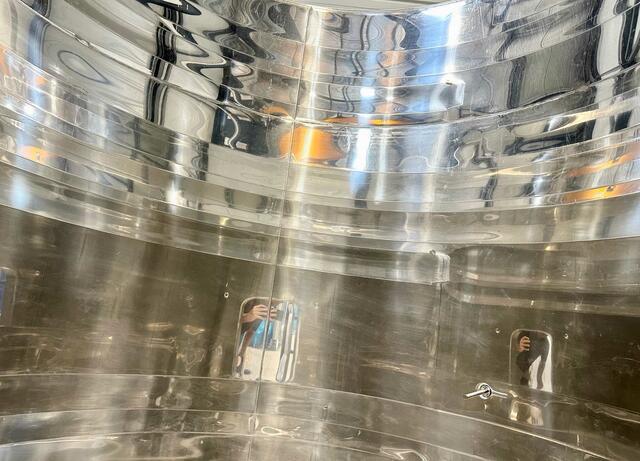

Bright annealing : What makes the inside of our new stainless steel tanks special

Properties and practical applications of this innovative technique

Bright annealing is a top-of-the-range finish for stainless steel, combining the perfection of thermal annealing with the incomparable shine of mechanical rolling. This technique gives our stainless steel tanks exceptional mechanical, aesthetic and chemical properties, making them ideal for meeting the most demanding requirements. In this article, we reveal the secrets of the bright annealing process, its many benefits and practical applications, demonstrating why it is the ultimate finish for guaranteeing quality and durability.

Definition and Process of the Bright Annealed Stainless Steel Finish

It is important to select the right finish to ensure optimum performance of the material.

Surface finish for stainless steel

The finish is of crucial importance when choosing a stainless steel, whatever its intended use. It determines the visual appearance for decorative applications, and is an integral part of the design to be specified. For non-decorative uses, the finish influences factors such as friction, wear, maintenance and corrosion resistance, so it must be chosen wisely and clearly detailed.Categories of finish

Stainless steel comes in a wide variety of standard and special finishes. They are generally divided into three families:

- Raw finishes

- Factory finishes

- Specialised finishes

Each category has a standard or common name. Some finishes may have more than one name, a potential source of misunderstanding.

Factory finishes, whether on hot-rolled or cold-rolled products, are the basis for finishes on flat stainless steel products. As well as being widely used for standard components, they are also the starting point for specialist finishes for industrial applications.

Types of finish

Four finishes are of particular importance in construction and architecture: 1D, 2D, 2B and 2R.

To optimise corrosion resistance on delivery, pickling follows hot rolling and annealing for factory finishes.

- 1D

This finish is the result of final hot rolling, followed by annealing and pickling. It gives a matt, slightly rough appearance, with low reflectivity. Common on thick sheets and plates, it was first used for non-decorative applications where surface appearance was of little importance, such as supports and structural elements. - 2D

After final cold rolling, it is annealed and pickled. The appearance is matt, with low reflectivity. This finish is suitable for industrial and architectural applications where appearance is not paramount. Relatively sensitive to fingerprints. - 2B

Similar to 2D up to the final stage where 2B products undergo a light cold rolling pass using highly polished rolls. This creates a slight surface strain-hardening that produces a brighter appearance. This is now the most widely used surface finish, also serving as the basis for polished and brushed finishes. Its surface remains relatively sensitive to fingerprints. - 2R

After final cold rolling, annealing in a controlled atmosphere produces an extremely smooth surface. A skin-pass (or temper-mill) operation - a rolling mill that imparts flatness, mechanical properties and surface finish (roughness, gloss, etc.) - enhances the shine. This ultra-smooth finish reduces the build-up of atmospheric contaminants and moisture compared with other finishes. It also makes cleaning easier.

|

|

Properties of the Bright Annealed Stainless Steel Finish

304L bright annealed steel is annealed in a controlled atmosphere, producing a very smooth surface whose shine is enhanced by a skin-pass operation. Its shine, slightly tarnished when seen from a distance, is similar to that of an old mirror, with a level lower than that of mirror-polished stainless steel. This extremely smooth surface is easy to clean.

Finish 2R = bright annealed

Also produced by cold rolling and pickling, this finish is finally annealed in a controlled atmosphere furnace. The absence of oxygen gives the stainless steel a reflective appearance. Its great flatness makes it suitable as a base for other finishes such as mirror polish or chrome plating.

Cold rolling of the material, followed by softening and pickling, produces a smoother, less rough surface.

Mechanical properties

Improved ductility :

- Definition: The ability of a material to deform plastically without breaking.

- Effect of annealing: Annealing reduces the hardness of stainless steel, increasing its ability to deform without breaking, which is crucial for forming and manufacturing operations.

- Applications: Allows stainless steel to be used in complex components requiring significant deformation without the risk of cracking.

Reducing internal constraints :

- Definition: Residual tensions present in the material after forming, welding or machining operations.

- Effect of annealing: Annealing relieves these stresses, reducing the risk of premature failure due to cracks or fractures.

- Applications: Annealed parts are more reliable and have a longer life, essential for critical applications such as aerospace or medical components.

Homogeneity of the microstructure :

- Effect of annealing: Annealing ensures a uniform distribution of alloying elements and a fine, homogeneous microstructure, improving the consistency of mechanical properties.

- Applications: Crucial for applications requiring tight tolerances and consistent performance, such as precision engineering.

Aesthetic propertie

Glossy appearance :

- Definition: Highly reflective surface that improves the visual appearance of stainless steel.

- Effect of lamination: Laminating gives a smooth, shiny surface, enhancing aesthetic appeal.

- Applications : Used in applications where appearance is crucial, such as architecture, interior design, and high-end consumer products.

Smooth surface :

- Definition: Surface free of roughness and defects, facilitating cleaning and maintenance.

- Effect of lamination: The lamination process eliminates roughness and imperfections, producing a perfectly smooth surface.

- Applications: Ideal for hygienic environments such as the food and pharmaceutical industries.

Chemical properties

Corrosion resistance :

- Definition: Ability of a material to resist chemical attack and degradation in corrosive environments.

- Effect of annealing and rolling: Annealing promotes the formation of a passive layer of chromium oxide, reinforced by rolling, preventing chemical reaction with the environment.

- Applications: Essential for marine, chemical and medical applications.

Easy to clean and disinfect :

- Definition: An easy-to-clean surface prevents the build-up of dirt, bacteria and contaminants.

- Effect of lamination: The smooth finish reduces the sites where contaminants can accumulate, making cleaning and disinfection easier.

- Applications: Crucial in industries where hygiene is paramount, such as food, beverages and pharmaceuticals.

Hygiene and Water Savings

The bright annealed finish of stainless steel offers considerable advantages in terms of hygiene and water savings.

Easy to clean

- Smooth surface: The extremely smooth surface achieved by the bright annealed finish makes it easy to clean, making this material ideal for environments where rigorous hygiene is essential.

- Deposit removal: Particles adhere weakly to the walls of bright annealed tanks and are easily removed by a simple water jet, reducing the amount of solid deposits in the wash water.

Water and chemical product savings

- Reduced water consumption: Tanks with a bright annealed finish optimise water consumption during washing and descaling processes, requiring less water due to the low adherence of particles.

- Fewer chemicals: Smooth surfaces require fewer chemicals for cleaning, reducing the introduction of substances into the waste cycle.

- Reduced cleaning times: Tanks with a bright annealed finish can be cleaned more quickly, reducing downtime and improving operational efficiency.

Environmental impact

- Less polluting wash water: Due to the low adherence of particles, washing and descaling water from bright annealed tanks is less polluted.

- Reduced pollution flow: The quantity of deposits remaining on the walls of the tank and their resistance to detachment are minimised, reducing the flow of pollution.

Precautions for use

- Avoiding scratches: It's important to take care of this type of vat room to avoid scratches, which could provide hanging points for limescale.

- Use of appropriate tools: Use coated tools and gentle removal methods to avoid damaging the smooth surface of the tanks.

In conclusion, bright annealing offers an unrivalled combination of durability, aesthetics and corrosion resistance for stainless steel tanks. With a smooth, bright surface, these tanks are easy to clean and maintain high hygiene standards, while reducing water and chemical consumption. Whether for industrial, food or chemical applications, bright annealing ensures superior performance and long life. Adopt this state-of-the-art finish to benefit from its many advantages and guarantee the quality and reliability of your stainless steel equipment.

→ Discover stainless steel tanks with bright annealed interior finish available from stock

#cuve #inox #recuit #brillant #surface #corrosion #ductilite