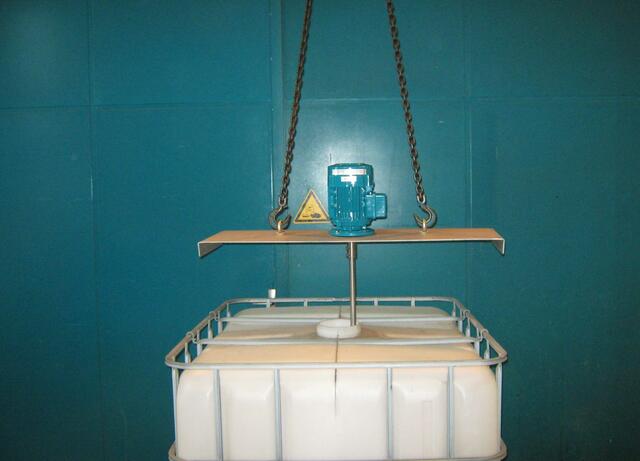

Propeller agitators for stainless steel tanks

Complete guide to optimised mixing

Propeller agitators play a crucial role in the processing industries, where the homogeneous mixing of materials is essential to guarantee the quality and efficiency of finished products. This equipment is specially designed to ensure uniform distribution of components in stainless steel tanks, making it indispensable in various industrial sectors requiring mixing tanks. Propeller agitators are particularly popular in the chemical, food and cosmetics industries, where they are used to mix, suspend and disperse substances in a controlled and efficient manner. Their ability to maintain the homogeneity of mixtures, even in demanding environments, makes them a preferred choice for professionals seeking to optimise their production processes.

| → Discover agitators | → Discover mixing tanks |

What is a propeller agitator?

A propeller agitator is a piece of equipment designed to homogenise materials inside stainless steel tanks in various industrial processes. Operating by means of an immersed rotating propeller, the agitator generates an axial or radial flow that induces the flow and shearing of materials. This movement effectively mixes liquids, suspensions and emulsions, ensuring uniform distribution of the components.

|

|

Technical process

Propeller agitators operate by rotating the impeller at a controlled speed, creating a cyclic flow pattern that prevents solid particles from settling to the bottom of the tank. The inclined blades of the propeller promote fluid movement from top to bottom, guaranteeing optimum homogenisation of materials, even in high-viscosity environments.

Differences between a propeller agitator and an industrial mixer

- Main objective :

A propeller agitator is specifically designed to maintain the homogeneity of mixtures, while an industrial mixer aims to quickly combine several components. - Design and use :

Propeller agitators are suitable for processes requiring constant, controlled mixing, ideal for applications in the chemical, food and cosmetics industries. Industrial mixers, on the other hand, are often used for faster mixing tasks and can handle larger volumes of materials in a shorter time. - Types of movement :

The propeller agitator generates a mainly axial or radial movement, suitable for uniform mixing and particle suspension. Industrial mixers can have various mechanisms, such as blades, ribbons or rotating drums, depending on the specific needs of the mixing process. Axial-flow turbines circulate the fluid parallel to the turbine's axis of rotation. These turbines have inclined blades that are less than 90° from the plane of rotation. The rotation of the turbine causes a cyclic flow pattern from top to bottom. The fluid at the top of the tank is forced to flow until it is diverted to the bottom of the tank. It then spreads to the bottom of the tank and rises along the wall before being sucked up by the turbine. This movement mixes the fluid from top to bottom and prevents solids and solutes from settling to the bottom of the tank.

The propeller agitators offered by Arsilac are used to process low-viscosity substances such as liquids, in order to homogenise, suspend or disperse materials. Axial flow agitators are therefore ideal for solid suspensions in liquids, as they prevent the deposition of solid particles.

Why choose a propeller agitator for a stainless steel tank?

Propeller agitators are essential equipment for stainless steel mixing tanks, offering a range of benefits that significantly improve the efficiency and quality of industrial processes. Here's why choosing a propeller agitator for a stainless steel tank is a wise decision to optimise your operations.

Specific advantages

- Efficient blending of mixtures

Propeller agitators ensure uniform distribution of the components, which is crucial for guaranteeing the quality and consistency of the final products. Thanks to their design, they can effectively mix liquids, suspensions and emulsions, even under high-viscosity conditions.

- Corrosion resistance

Stainless steel agitators are renowned for their corrosion resistance, making them ideal for demanding production environments. This ensures long life and optimum performance without the risk of chemical degradation.

- Easy to clean and hygienic

Cleaning and maintenance of stainless steel agitators is simpler and more efficient, which is essential for the food and pharmaceutical industries where hygiene is paramount. Agitators can be easily dismantled and cleaned, reducing the risk of contamination and ensuring compliance with strict sanitary standards.

- Durability and longevity

Stainless steel is a durable and robust material, capable of withstanding extreme operating conditions, including high temperatures and corrosive environments. Propeller agitators installed in mixing tanks benefit from this robustness, providing a reliable and durable mixing solution.

- Energy efficiency

Propeller mixers are optimised to maximise mixing effect while minimising energy consumption. Their efficient design results in significant energy savings, reducing operating costs while guaranteeing high-quality performance.

Propeller agitator applications

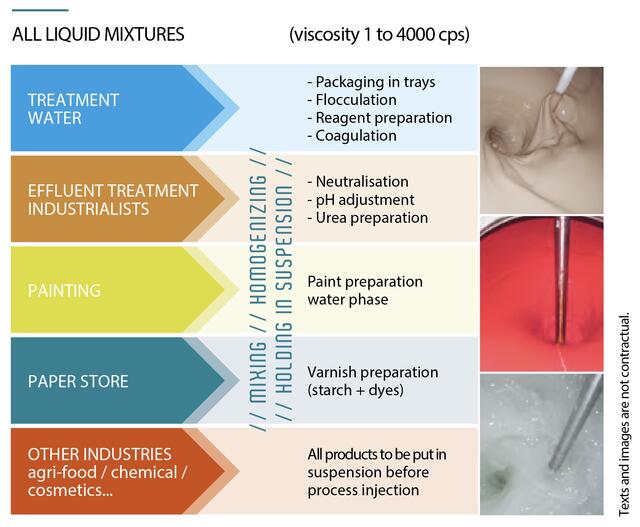

Propeller agitators are used in a variety of industrial sectors for mixing and homogenising applications, thanks to their efficiency and adaptability to different types of fluid and process. Here is an overview of their main industrial uses and examples of the products they can handle.

Use in various industrial sectors

- Chemical industry

Propeller agitators are essential for chemical synthesis, dissolving and dispersing reagents, and maintaining homogeneous suspensions. They facilitate chemical reactions by ensuring efficient mixing of reagents and promoting the heat transfer required for chemical processes.

- Pharmaceutical industry

In drug production, propeller agitators are used for mixing active ingredients and excipients, for suspensions and solutions, and for fermentation in bioprocesses. Their precision and ability to maintain sterile conditions are crucial to guaranteeing the quality and safety of pharmaceutical products.

- Food industry

Propeller agitators play a key role in the manufacture of food and beverage products, including dairy products, fruit juices, sauces and soups. They ensure constant homogenisation, which is essential for maintaining the texture and quality of food products. In breweries, for example, they are used to mix wort and yeast during the fermentation process.

- Cosmetics industry

For the manufacture of cosmetic products such as creams, lotions, shampoos and gels, propeller agitators ensure uniform dispersion of the ingredients, guaranteeing optimum consistency and texture. They are also used to emulsify oils and waters, which is essential in many personal care products.

- Water and effluent treatment

Propeller mixers are used in water treatment plants to homogenise activated sludge, mix treatment chemicals and improve sludge sedimentation and thickening. Their efficiency enables large quantities of water and sludge to be treated uniformly and economically.

- Mining industry

In the mining sector, propeller shakers are used for mineral processing, including leaching, precipitation and flotation. They help to keep particles in suspension and ensure a homogeneous mixture of the chemicals used in mineral processing.

Examples of mixed products

- Cosmetics :

Moisturisers, lotions, shampoos, shower gels. - Pharmaceuticals :

Medicated suspensions, injection solutions, fermentation products. - Food products :

Dairy products (milk, yoghurt), fruit juices, sauces, soups, fermented drinks (beer). - Chemical products :

Chemical reagents, suspensions, dispersions, emulsions.

Factors to consider when choosing a propeller agitator

When choosing a propeller agitator for a stainless steel tank, there are a number of key factors to take into account to guarantee mixing efficiency and quality. Here are the main factors to consider:

Viscosity of liquids

The viscosity of a liquid is a crucial property that directly influences the choice of agitator. Viscosity measures a liquid's resistance to flow and is determined by the nature of the product and its temperature. Here's how viscosity affects the choice of agitator:

- Low viscosity liquids :

These liquids, such as water (1 Cp) and ethanol (1 Cp), have little resistance to flow. They require agitators capable of operating at relatively high speeds with moderate power consumption to ensure adequate mixing. - High viscosity liquids :

Substances such as mayonnaise (2000 Cp) or liquid honey (6000 to 10000 Cp) require more powerful agitators capable of transmitting sufficient mechanical energy to achieve a uniform state of flow and mixing. The higher the viscosity, the greater the power required by the agitator.

Operating temperature

The temperature of the liquid in the tank also influences the performance of the propeller agitator:

- Effect on viscosity :

An increase in temperature can reduce the viscosity of the liquid, making it more fluid and easier to mix. Conversely, a drop in temperature can increase viscosity, requiring a more powerful agitator. - Stability of materials :

Certain agitator and vessel materials must be compatible with operating temperatures to avoid degradation or corrosion. For example, stainless steel is often chosen for its corrosion resistance and ability to withstand high temperatures.

Mixing objectives

The specific mixing objectives will also determine the type and configuration of propeller agitator to be used:

- Homogenisation :

Ensuring uniform distribution of components in the mixture, essential for food, pharmaceutical and cosmetic products. - Suspension :

Keeping solid particles in suspension in a liquid to prevent them settling to the bottom of the tank. This is crucial in processes such as fermentation or leaching in the mining industry. - Dispersion :

Mixing immiscible substances, such as water and oil, to create emulsions. Propeller agitators are generally used to disperse solids in liquids or liquids in other liquids, ensuring optimum interaction between the components.

types of agitators offered by arsilac

Understanding the principle of viscosity in detail

Viscosity is an important property to consider when choosing the right agitator for your needs. It represents a liquid's resistance to flow and varies according to the temperature of the product. The higher the viscosity, the greater the mechanical energy transmitted by the rotary agitator must be to achieve a sufficient state of flow.

Low viscosity liquids exhibit little resistance to flow and therefore require relatively small amounts of energy per unit volume for a mixing condition to occur. High viscosity liquids attenuate the mechanical energy transmitted by a rotating agitator and require relatively large amounts of power per unit volume to achieve a flow condition large enough for adequate mixing to occur.

Viscosity is measured in Pascal/second or centipoise.

1mPascal/second = 1 centipoise (symbol: Cp)

1 Pascal/second = 1000 Cp

A product such as vinaigrette will have a viscosity of between 1300 and 2600 mPa/s (Cp); in other words, between 1300 and 2600 centipoise or between 1.3 and 2.6 pascal/second.

It is important to bear in mind the following situations:

- If the temperature of the product being mixed increases, the viscosity of the material will decrease and the liquid will become more fluid;

- if the motor speed decreases, the agitator can work with thicker products and thus mix higher viscosities.

List of viscosities suitable for agitators available from Arsilac

⚠️ For a temperature maintained at 23°, here are the viscosities known to Arsilac :

| - Water = 1 Cp - Ethanol = 1 cp - Milk = 2 to 10 Cp - Fruit juice = 2 to 5 Cp - Olive oil = 85 to 100 Cp - Cream = 10 Cp - Linseed oil = 28 Cp - Glycol = 40 Cp - Palm oil = 45 Cp - Peanut oil = 40 Cp - Coconut oil = 60 Cp - Corn oil = 72 Cp - Soup = 85 Cp - Olive oil = 80 to 100 Cp - Castor oil = 100 Cp - Molasses with 65% sugar = 120 Cp - Hydraulic oil = 120 Cp - SAE 10 engine oil = 85 to 140 Cp - Yoghurt = 150 Cp - SAE 20 engine oil = 140 to 420 cps - SAE 30 engine oil = 420 to 650 cps - SAE 40 engine oil = 650 to 900 cps - Rapeseed oil = 160 - Chocolate sauce = 280 cp - Engine oil SAE 15W40 = 390 Cp - Molasses with 70% sugar = 400 Cp - Liquid wax = 500 Cp - Fruit must = 600 Cp - Engine oil SAE 40 = 650 - 900 Cp - Varnish = 900 Cp |

- Ketchup = 1000 Cp - Vinaigrette, salad dressing = 1300 to 2600 Cp - Baby food = 1400 Cp - Glycerine = 1500 Cp - Chocolate mousse = 1500 Cp - Apple purée = 1500 Cp - Mayonnaise = 2000 cp - Concentrated fruit juice = 2500 Cp - Shampoo = 3000 Cp - Polyester resin = 3000 Cp - Maple syrup = 2500 to 5000 Cp - Condensed milk = 6000 Cp - Hand cream = 8000 Cp - Jam = 4000 to 8500 Cp - Malt extract = 9500 Cp - Liquid honey = 6000 to 10000 Cp - Soft cheese = 30000 Cp - Butter = 30000 Cp - Mustard = 70,000 Cp - Toothpaste = 70,000 Cp - Sour cream = 100,000 Cp - Tar 100 000 to 10 000 000 Cp - Peanut butter = 250,000 Cp - Lard = 1,000,000 Cp - Putty = 100,000,000 Cp - Pitch = 2 300 000 000 Cp |

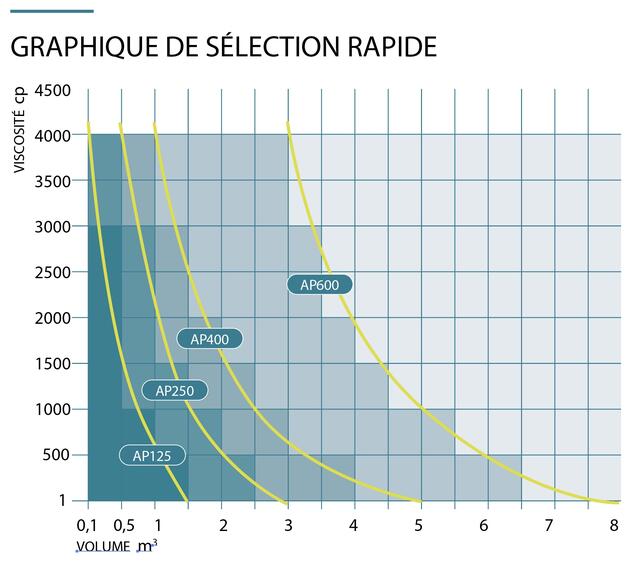

HOW TO CHOOSE THE RIGHT MIXER

Choosing and sizing a mixer can be a complicated decision. The specific design, operating layout and power requirements of agitators play a part in selecting the right equipment for the quality of the finished product.

To assess your needs, Arsilac takes 3 criteria into account:

- the nature of the bulk products to be mixed

- the purpose of the mixing

- the type of process and its environment

→ Technical documentation available online for more details on the propeller mixers on offer

Do you have any questions ?

Do not hesitate to contact Arsilac to discuss your project and define the equipment best suited to your production or operating constraints.

#arsilac #agitateur #melange #cuve #process